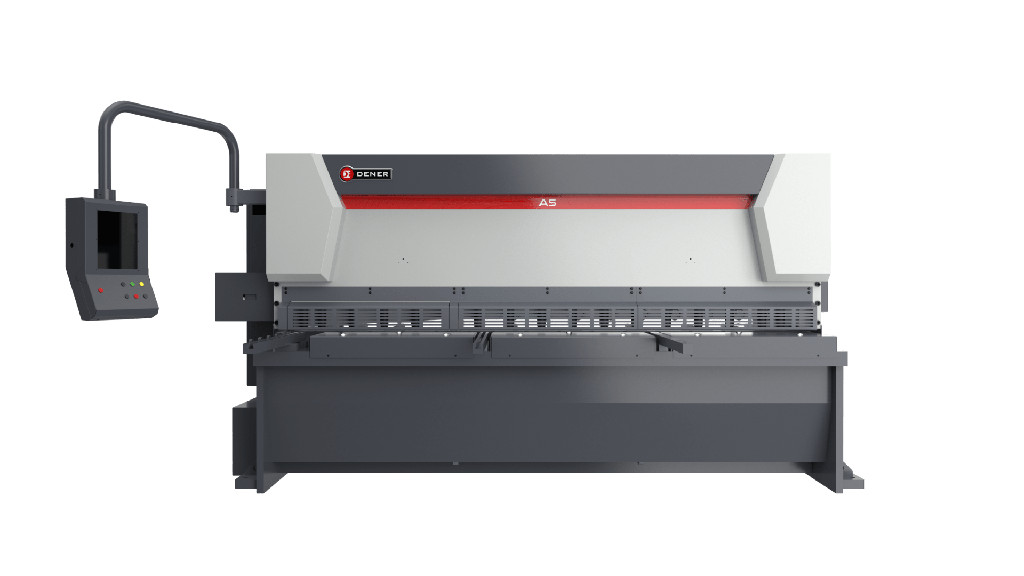

AS type CNC shear

Marque : DENER

Brand: DENER

Caractéristiques :

Faster and higher-quality cuts.

Robust and durable structure.

Automatic blade gap and cutting angle adjustment.

Automatic backgauge adjustment.

High precision and easy operation.

Low maintenance costs.

Enhanced safety.

Globally recognized and reliable components.

Faster and higher-quality cuts.

Robust and durable structure.

Automatic blade gap and cutting angle adjustment.

Automatic backgauge adjustment.

High precision and easy operation.

Low maintenance costs.

Enhanced safety.

Globally recognized and reliable components.

CNC shear

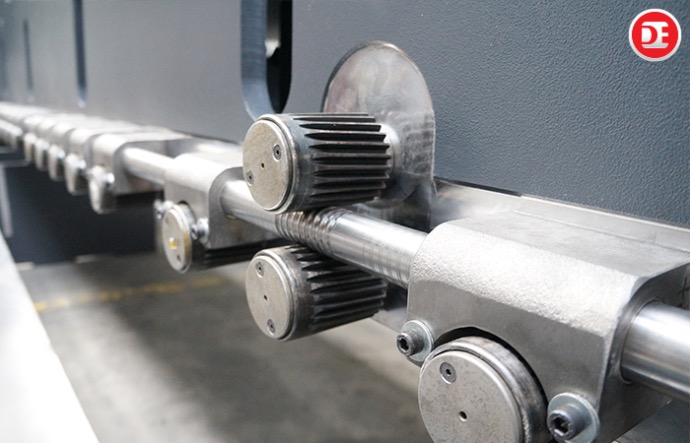

Dener CNC shears feature a robust mechanical structure, powered by hydraulic cylinders, with ball screw-guided movement ensuring both reliability and precision. This system is paired with a user-friendly CNC controller. Dener shears offer cutting capacities from 6 mm to 20 mm thickness for mild steel (45 kg), with standard cutting lengths ranging from 3 m to 6 m. For other dimensions, please contact us.

Their monobloc frame guarantees maximum rigidity and high resistance to torsion, delivering high-quality cuts. The operator simply inputs the material thickness and type, and the ESA S 530 controller automatically adjusts the cutting angle and blade gap.

ESA S 530 Controller

7″ TFT LCD screen • Backgauge control • Blade gap adjustment • Cutting angle adjustment • Cutting length setting • Programmable up to 100 steps

Front Safety Guard

Front safety guard along the entire cutting length. Can be disengaged over 1000 mm for small parts.

Monobloc Structure

A robust monobloc frame providing exceptional cutting quality from 6 mm to 20 mm.

Réglage entre lames automatique

Automatic blade gap adjustment system ensures precise cuts every time.

Backgauge

Motorized backgauge with fast positioning and a precision of ± 0.1 mm.

Pneumatic Removable Rear Sheet Support

Supports thin sheets during cutting, preventing distortion or warping.

standard

Equipements

ESA S 530 CNC Control Unit

Automatic adjustment system for cutting angle and blade gap

Hydraulic sheet holders

Front ball transfer table

Pneumatic removable rear sheet support

Front sheet supports with graduated square ruler

Motorized backgauge

Remote foot pedal with emergency stop button

Front safety guard with protective grille

LED lighting on cutting line

CE-compliant safety system

More details

Options

- Manual centralized lubrication system

Oil temperature maintenance system

Pneumatic free-roller sheet follower

Cutting laser

need more informations ?

Contact us !