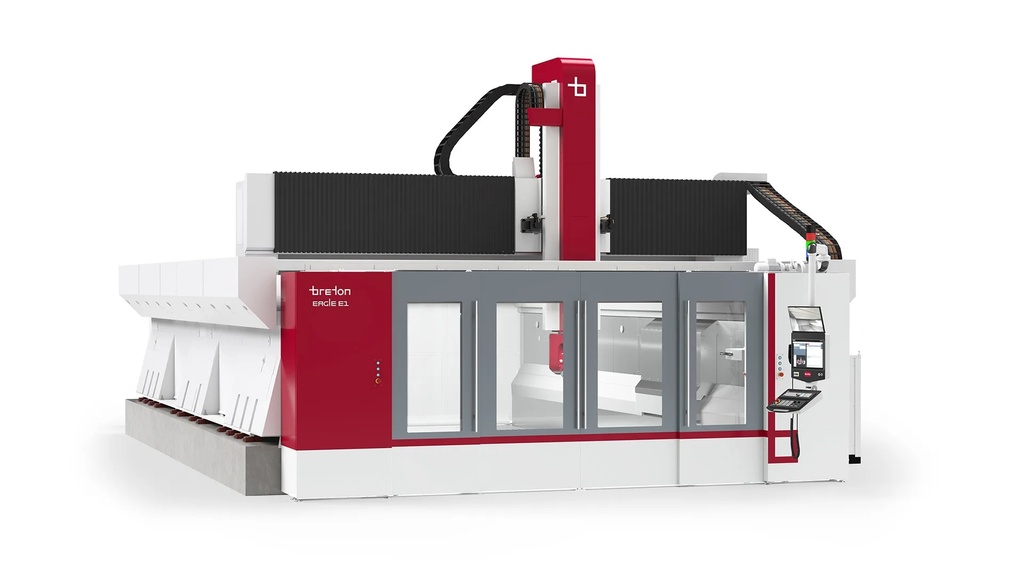

Eagle

Brand: BRETON

Caractéristiques :

Breton Eagle is a modular and versatile machining center designed for diverse applications, offering numerous options such as ultrasonic cutting and thickness control. Its adjustable dimensions include vertical strokes up to 2.5 m and column extensions exceeding 12 m. Engineered for wet or dry machining, it incorporates advanced protections against contaminants. The thermosymmetric design enhances thermal management, while the Hornet and Ghibli heads deliver performance tailored to precision and power requirements.

Breton Eagle is a modular and versatile machining center designed for diverse applications, offering numerous options such as ultrasonic cutting and thickness control. Its adjustable dimensions include vertical strokes up to 2.5 m and column extensions exceeding 12 m. Engineered for wet or dry machining, it incorporates advanced protections against contaminants. The thermosymmetric design enhances thermal management, while the Hornet and Ghibli heads deliver performance tailored to precision and power requirements.

Dynamic 5-axis vertical gantry machining center with modular structure

The wide range of available structural combinations allows for a custom configuration based on the required work volumes. The technical equipment makes it ideal for high-speed precision machining on complex three-dimensional shapes made of lightweight alloys, resin, or composite materials.

Heads compatible with Eagle:

Ghibli

Ghibli HD

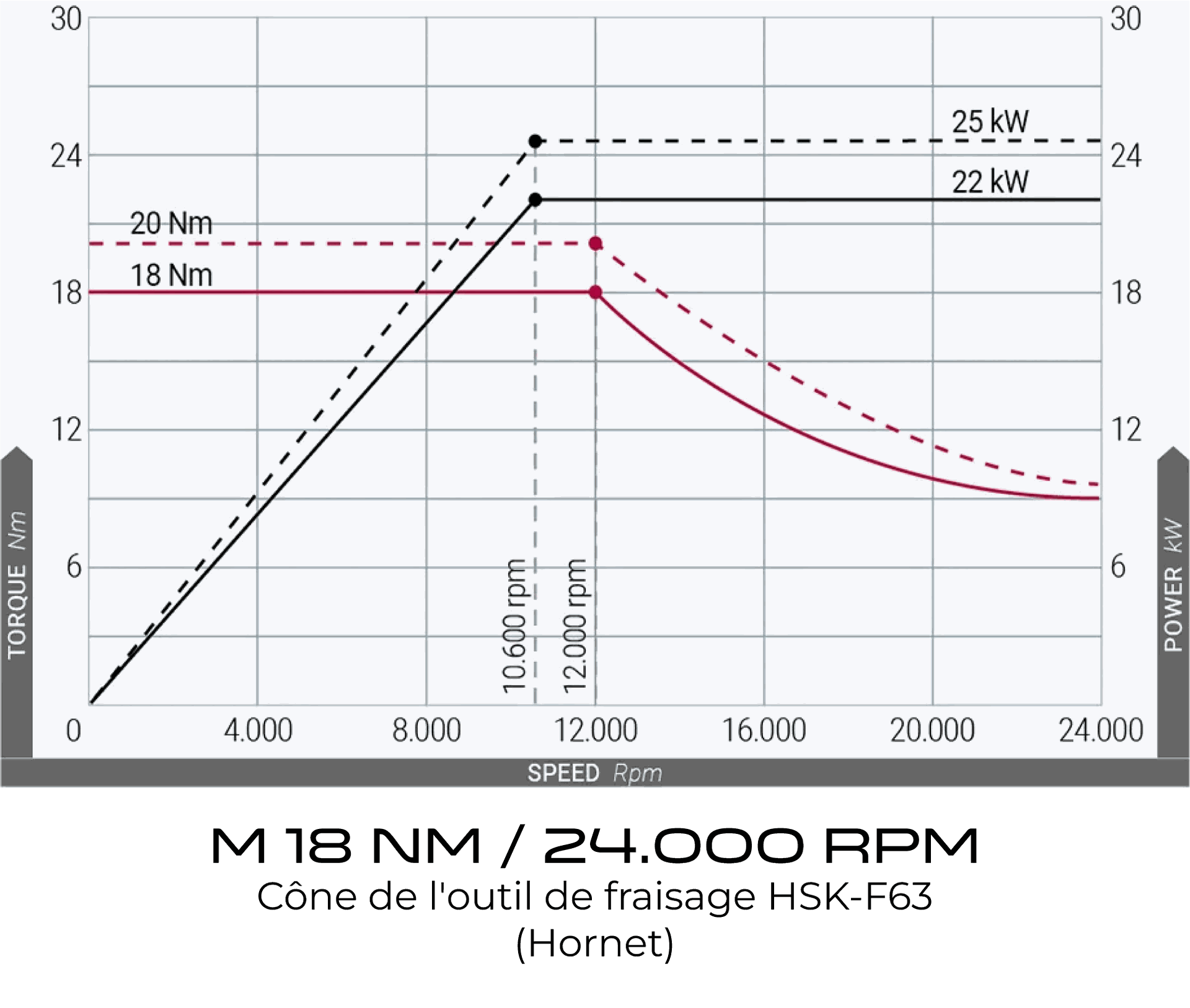

Hornet

HORNET, ANGULAR HEAD WITH A UNIQUE DESIGN

Designed with a double offset of the spindle axis, the Hornet head optimizes accessibility and precision.

HIGH MODULARITY

Eagle is entirely made of electro-welded steel and is sized using finite element analysis to reduce vibrations and limit torsions; this choice meets the dimensional modularity requirements set by machine users, allowing Breton to easily customize the standard product to meet market demands.

THERMOSYMMETRIC DESIGN

Eagle is a high-column gantry machining center, with a balanced vertical axis and using heads with a symmetrical structure to achieve constant thermal expansion.

Eagle's thermosymmetric design helps reduce structural deformations and allows for easy correction through software. The points where heat is generated (such as the head, the A-axis, and the electrospindle) are cooled to reduce heat transfer to other parts of the structure.

DUAL DRIVE MOTORS (DOUBLE DRIVE)

The carriage and crossbeam are equipped with high-performance motors using Dual Drive technology.

This solution ensures high force for the heaviest operations by using the power of both motors pushing to the maximum in the same direction. For high-precision operations, the preload is automatically increased to achieve the highest level of accuracy. The Dual Drive system consumes less energy than linear motors and does not require dedicated cooling systems.

COMPATIBLE WITH ULTRASOUND CUTTING HEAD

The ultrasonic cutting head allows cuts to be made on honeycomb materials without tearing or chipping them. This tool is handled like a standard tool and is indeed stored in the regular tool magazine.

CONICAL MACHINING CONTROL HEAD

A conical machining control head, automatically managed by the CNC, allows for checking the actual position of the hole on the workpiece before performing the conical machining.

The head detects the actual position of the holes on the workpiece using a physical system or a 3-point laser, in order to establish their exact coordinates before conical machining. Compared to a traditional probing cycle, the time and thus costs are significantly reduced.

ENERGY REGENERATION DURING BRAKING

It enables inline regeneration of braking energy; thus, no energy is dissipated through the braking resistor.

need more informations ?

Contact us !