Genesi

Brand: BRETON

Caractéristiques :

Genesi is a range of machining centers for additive manufacturing, offering large material deposition capabilities and precise control of printing parameters via extrusion systems developed by Breton. Its AI software automatically optimizes process settings. Combining additive printing and milling options, it provides enhanced flexibility. Breton ensures a safe, standards-compliant work environment and supports clients with expert guidance for successful integration into their businesses.

Genesi is a range of machining centers for additive manufacturing, offering large material deposition capabilities and precise control of printing parameters via extrusion systems developed by Breton. Its AI software automatically optimizes process settings. Combining additive printing and milling options, it provides enhanced flexibility. Breton ensures a safe, standards-compliant work environment and supports clients with expert guidance for successful integration into their businesses.

3D printer for additive manufacturing by thermoplastic material extrusion

Genesi is the product line from Breton dedicated to the additive manufacturing sector. Starting from an in-depth analysis of extrusion processes, Breton has developed a wide range of machining centers to harness the potential of Large-Format Additive Manufacturing using thermoplastic materials.

Available versions and models:

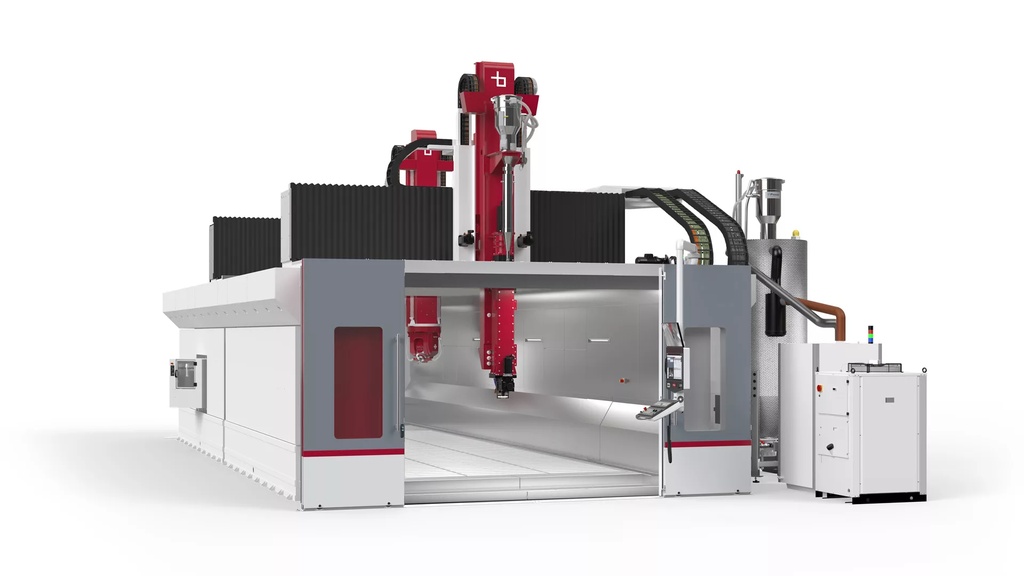

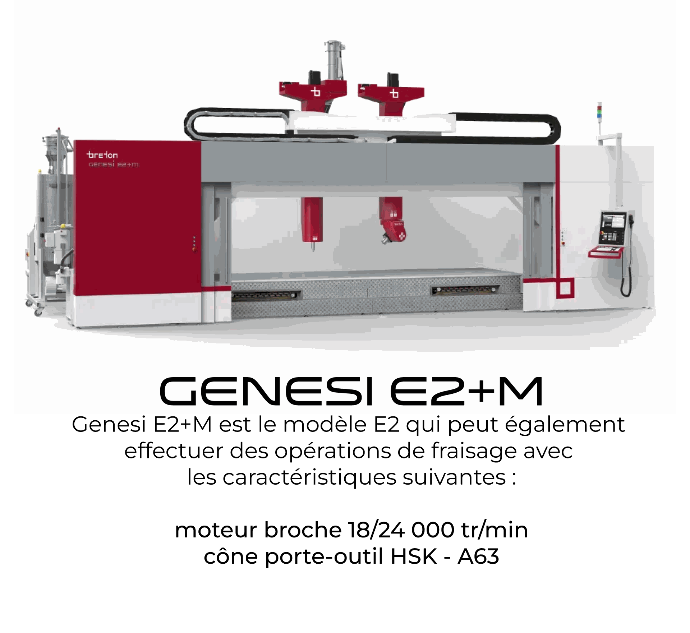

Genesi E2

The E2 series of Breton Genesi has a maximum extrusion capacity of 60 kg/h and includes 3 models: these differ in their working area, footprint, and additional milling processes.

Genesi E3

The E3 series of Breton Genesi has a maximum extrusion capacity of 200 kg/h and, thanks to its modular design, is available in various sizes, either for pure additive manufacturing or with additional milling capabilities.

PREDICTIVE PRODUCTION

Use of machine learning algorithms and AI to ensure high mechanical and aesthetic properties.

LARGE DIMENSIONS

3D printer capable of producing large-scale prototypes, up to 3 meters in height and 5 meters in length/width.

TEMPERATURE CONTROL

Closed system with heated table and thermal cameras to monitor the temperature of the parts.

SW CANOVA

Post-processing software that automatically adjusts parameters according to the machine and material to prevent errors.

Need more informations ?

Contact us !