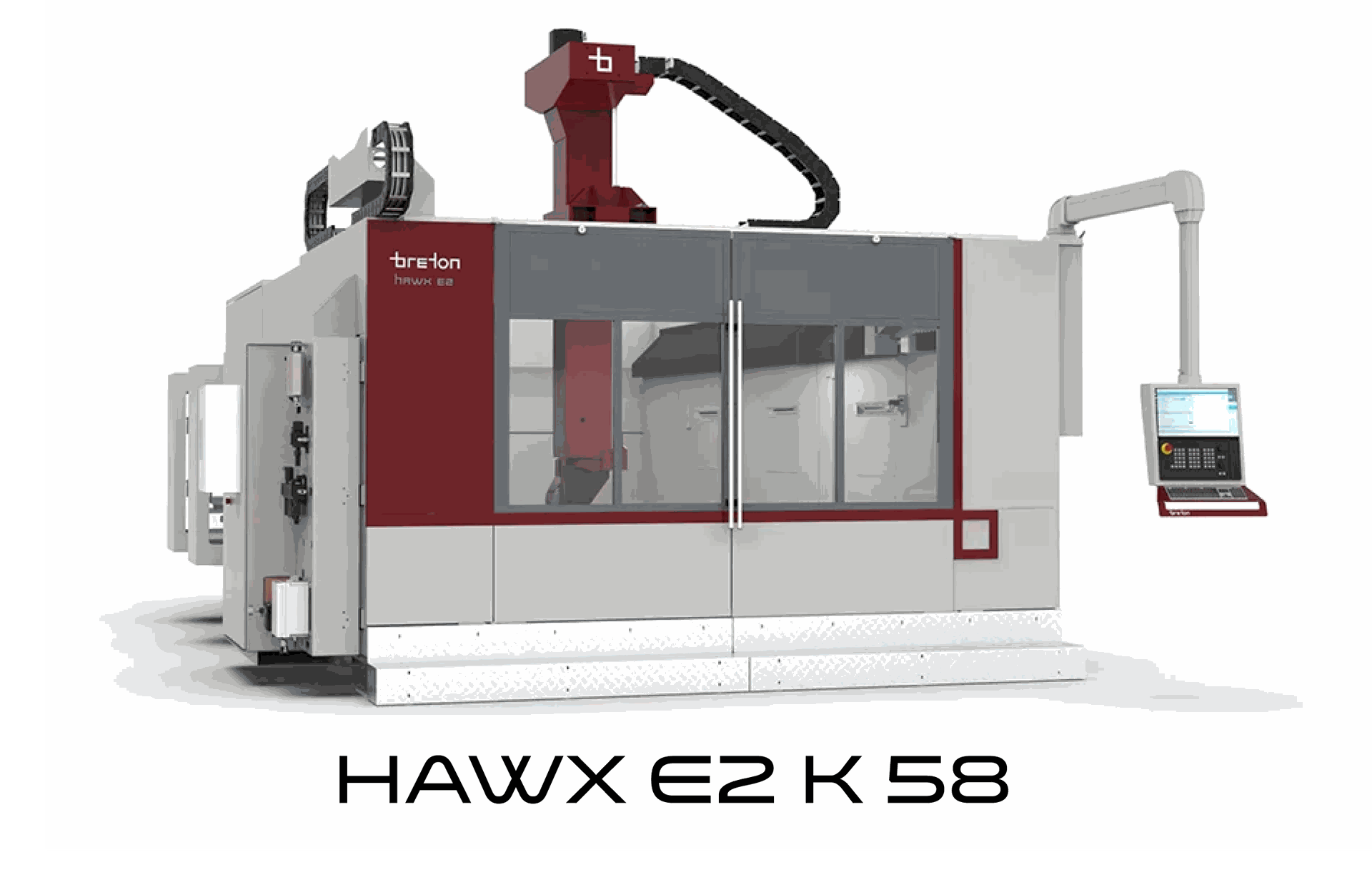

Hawx

Brand: BRETON

Caractéristiques :

Breton's HAWX delivers exceptional precision and stability with its monolithic structure and compact design for optimized space usage. It supports dry and wet machining, featuring advanced protections against dust and liquids. Equipped with a dual safety system and anti-collision technology, it minimizes errors. Its energy-efficient design reduces maintenance costs and enhances operational efficiency. Reliability is ensured through high-quality components and a responsive support service, maximizing machine availability and performance.

Breton's HAWX delivers exceptional precision and stability with its monolithic structure and compact design for optimized space usage. It supports dry and wet machining, featuring advanced protections against dust and liquids. Equipped with a dual safety system and anti-collision technology, it minimizes errors. Its energy-efficient design reduces maintenance costs and enhances operational efficiency. Reliability is ensured through high-quality components and a responsive support service, maximizing machine availability and performance.

Dynamic 5-axis vertical machining center with a modular gantry and an extendable configuration.

The right combination of strength and stability makes it ideal for high-speed milling and deburring operations on complex three-dimensional parts made of light alloys, resin, or composite materials.

Available versions and models:

Hawx E1

The Hawx E1 is built with a self-supporting, monolithic structure whose central core provides high robustness and allows for easy handling.

Hawx E2

The Hawx E2 is a base model made of a self-supporting monolithic structure, which can be shipped fully assembled and extended along the machine’s X-axis by adding additional modular bases.

Hornet

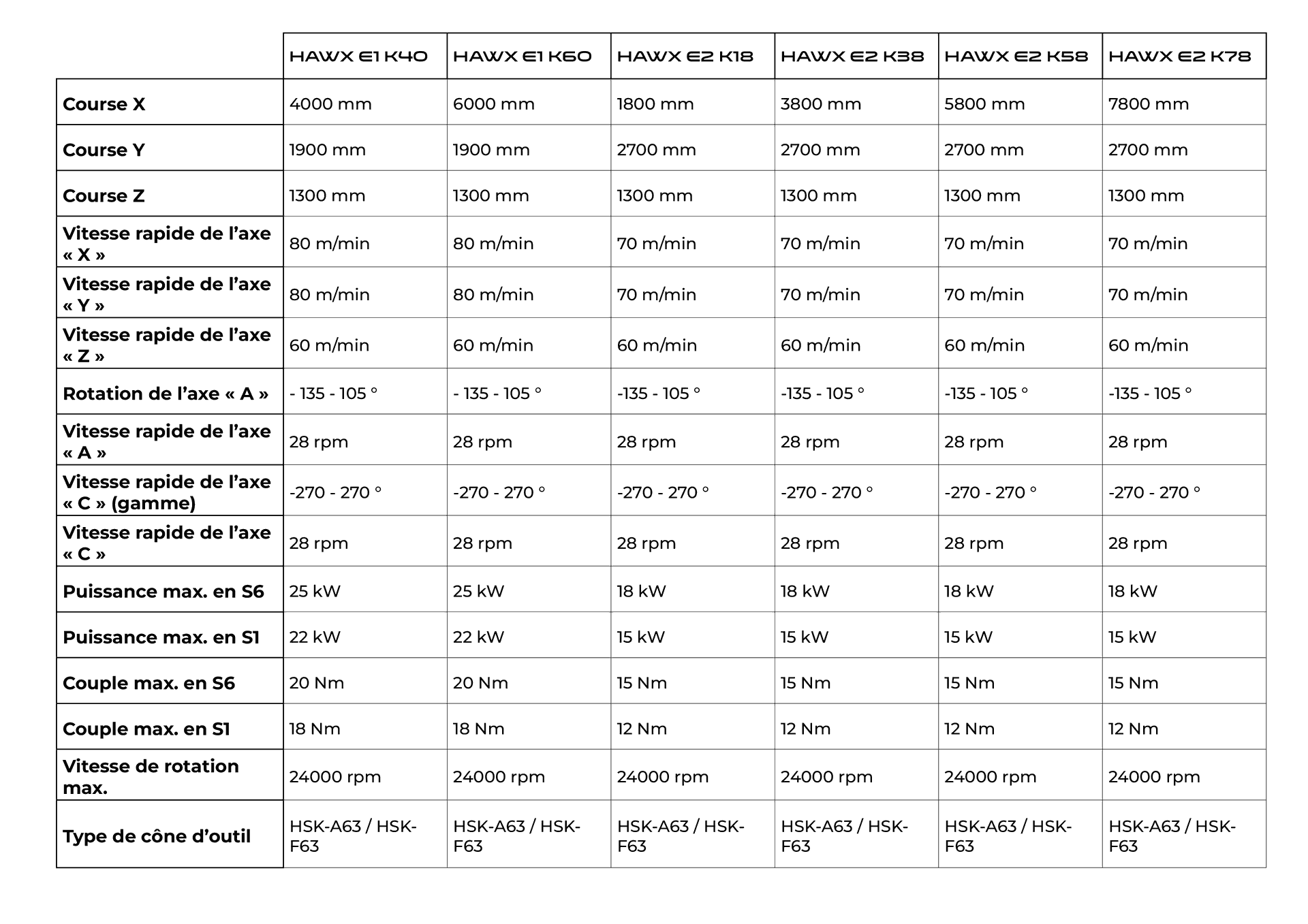

Comparison table of versions

MACHINE DESIGNED FOR DELIVERY FULLY ASSEMBLED

The HAWX is delivered pre-assembled with a wired cabinet, ready to operate within 5 days, including commissioning and training. It can be easily relocated at the customer’s site.

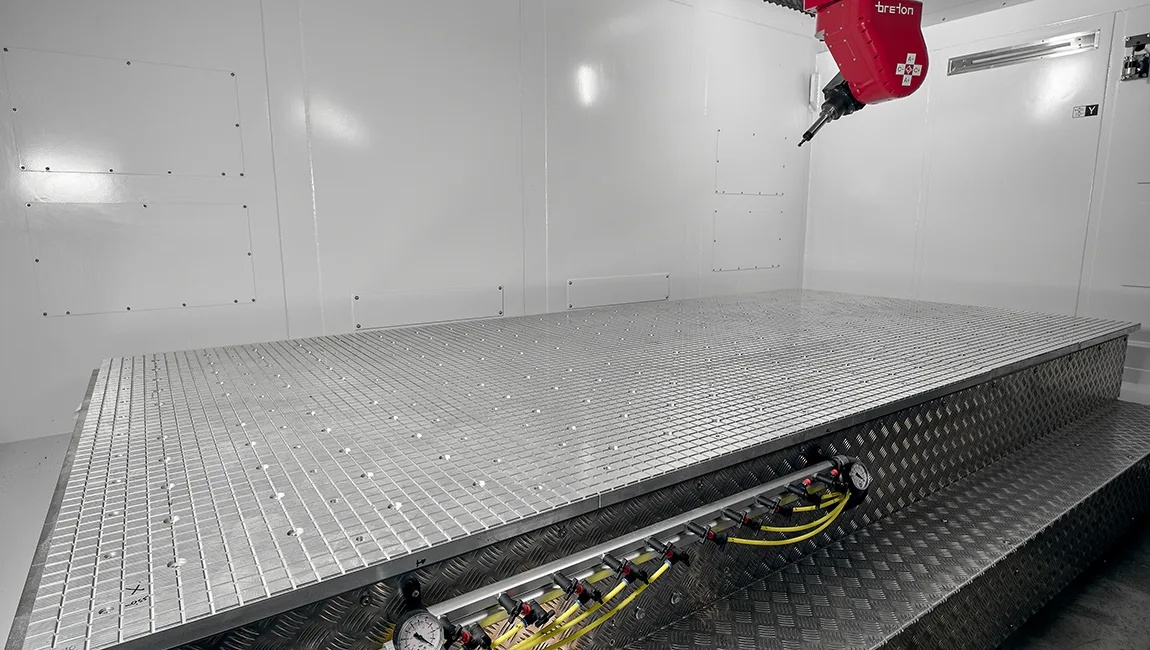

SELF-SUPPORTING MONOBLOC MODULAR BASES

The Hawx E1 and E2 feature a robust, self-supporting structure, with the option to extend the machine using modular bases.

VARIOUS SOLUTIONS AVAILABLE

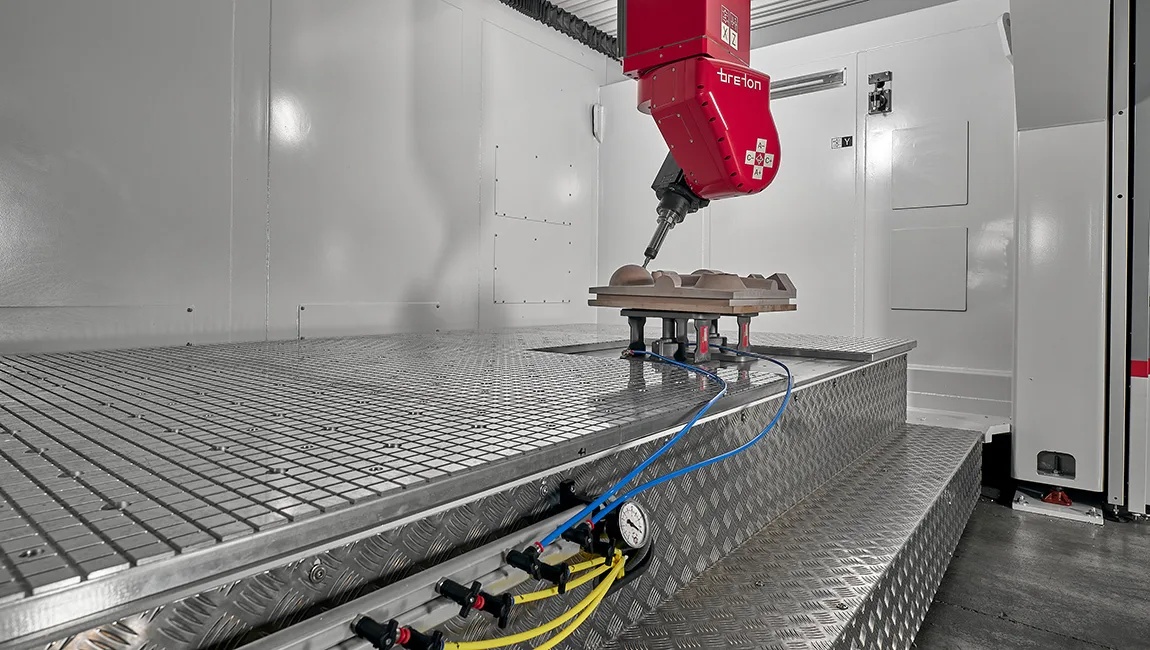

Several workload automation configurations are available, including mechanical clamping, vacuum grid, suction cups, and pallet changer.

EXTERNAL TOOL MAGAZINE

The 8-position tool magazine, located outside the machining area, is dust-protected and easily accessible to the operator. The capacity can be extended up to 64 positions.

“BOX-IN-BOX” ARCHITECTURE

This architecture enhances rigidity and precision, even during demanding applications.

HORNET, UNIQUELY DESIGNED ANGULAR HEAD

Designed with a double offset of the spindle axis, the Hornet head optimizes accessibility and precision.

SIEMENS SINUMERIK ONE CNC CONTROL

The HAWX is equipped with the latest generation Siemens Sinumerik One CNC.

need more informations

Contact us !