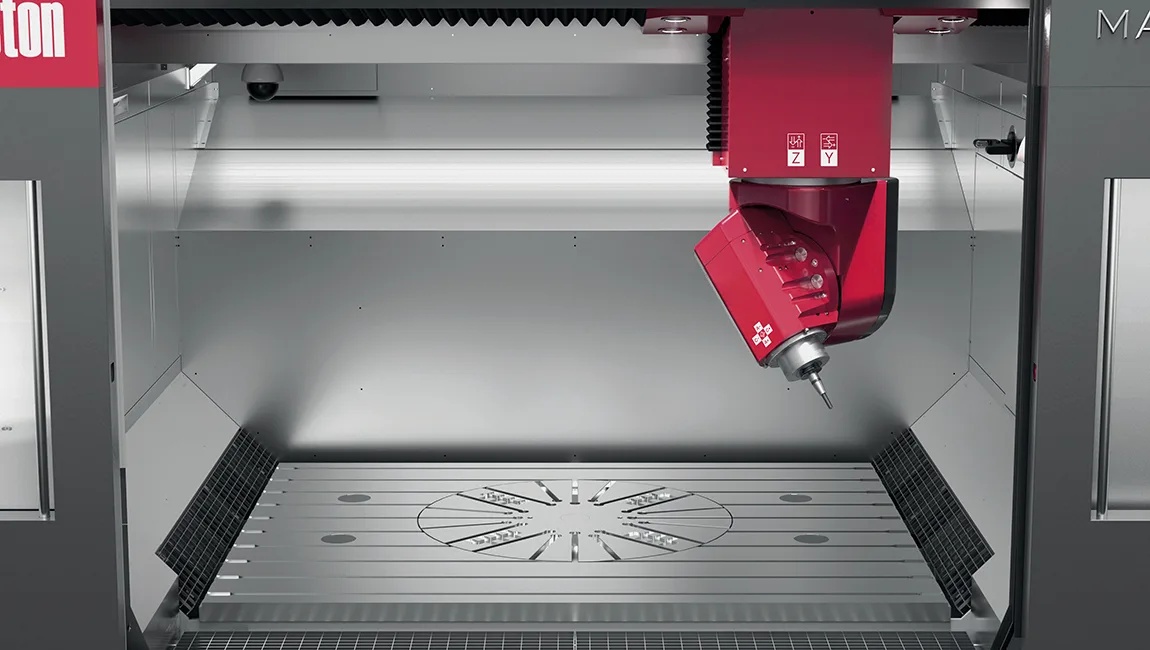

Matrix E1

Brand: BRETON

Caractéristiques :

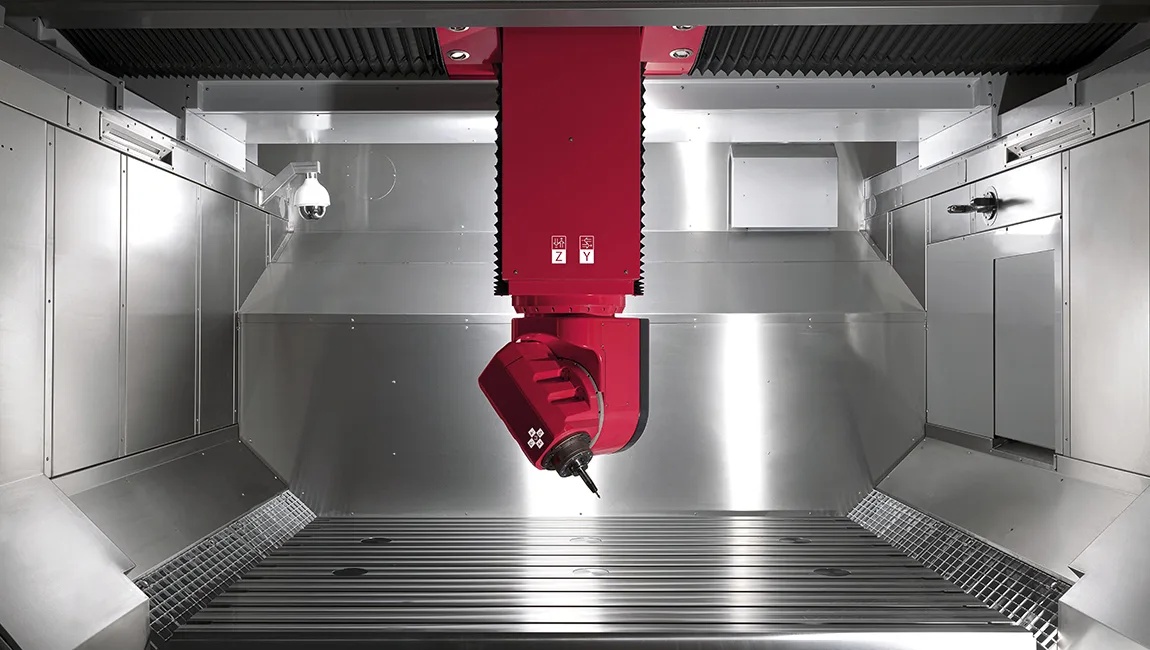

The Matrix E1 combines compactness and efficiency, offering extended travel within a reduced footprint, ideal for machining large parts. Its thermosymmetric structure with Thermal Shield ensures precision and stability without costly cooling systems. Preassembled, it minimizes installation costs. Equipped with direct drive motors, versatile accessories, and high adaptability, it performs effectively on materials like steel and aluminum. Advanced lubrication and optimized chip management lower operating costs and simplify maintenance.

The Matrix E1 combines compactness and efficiency, offering extended travel within a reduced footprint, ideal for machining large parts. Its thermosymmetric structure with Thermal Shield ensures precision and stability without costly cooling systems. Preassembled, it minimizes installation costs. Equipped with direct drive motors, versatile accessories, and high adaptability, it performs effectively on materials like steel and aluminum. Advanced lubrication and optimized chip management lower operating costs and simplify maintenance.

Dynamic and precise 5-axis monoblock gantry vertical machining center.

Available in different configurations to best meet the needs of specific applications, including molding, aerostructures, and machining of composite materials. It is ideal for high-speed roughing, semi-finishing, and finishing operations on medium-sized parts made of steel, light alloys, or special composite materials.

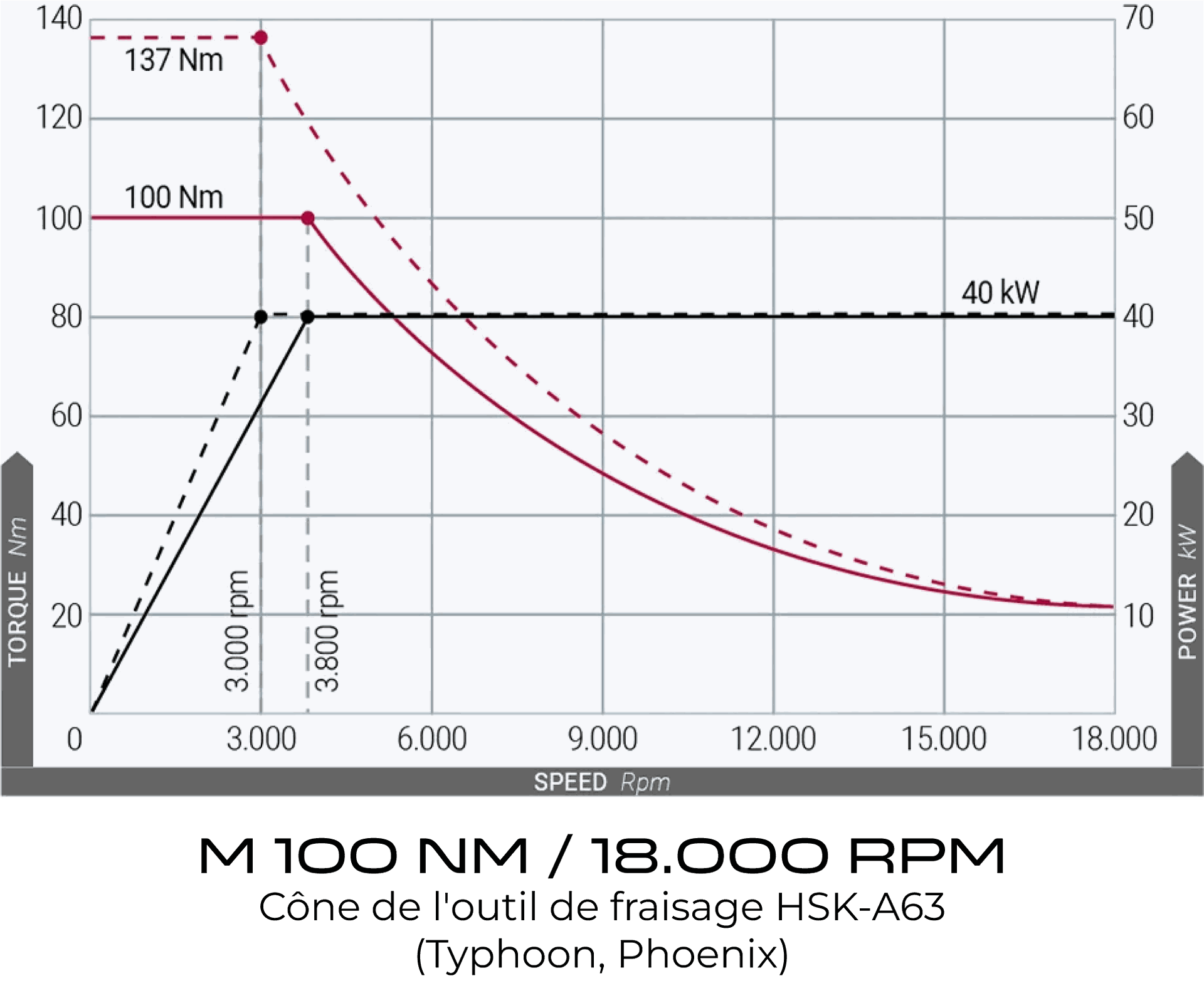

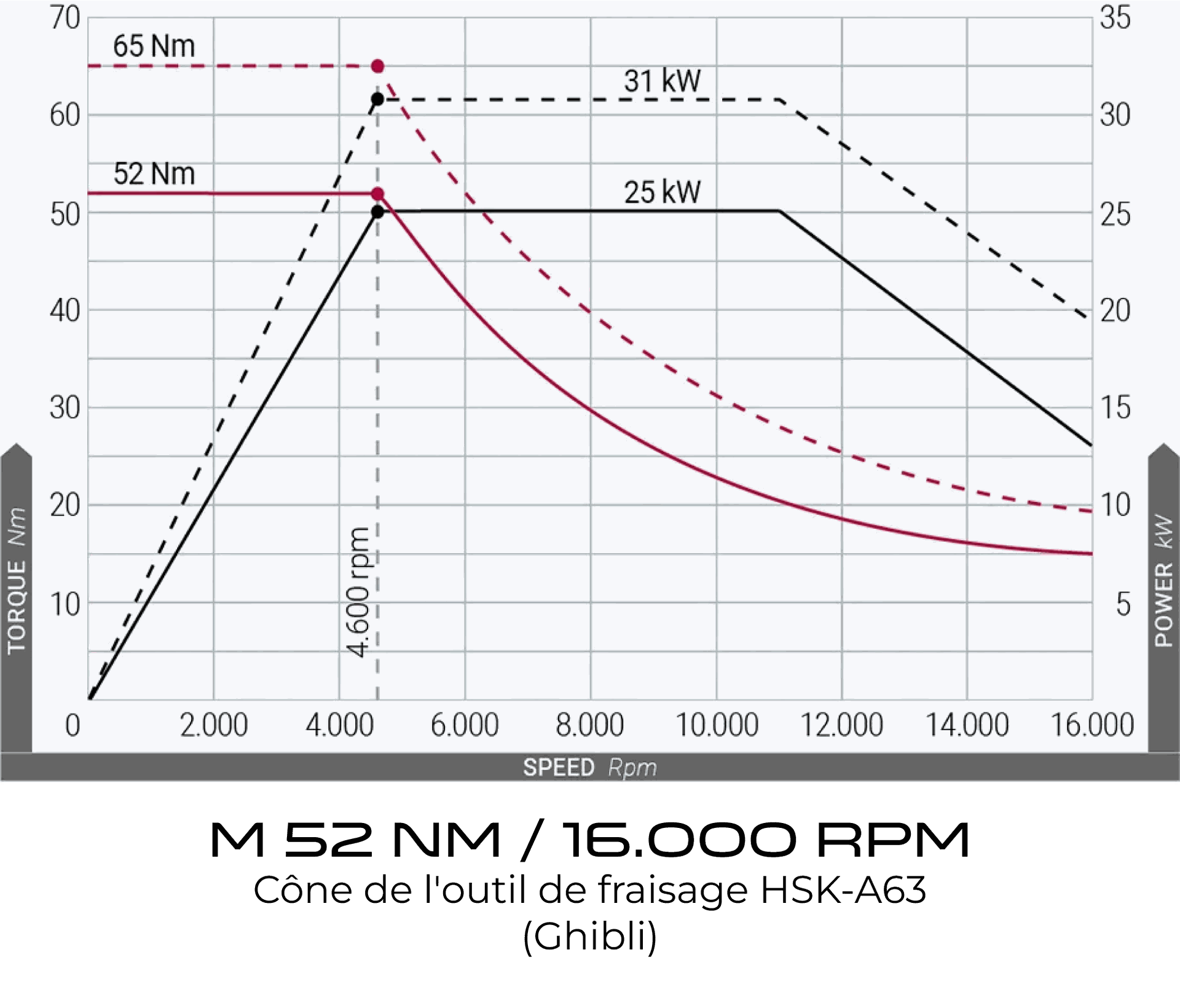

Heads compatible with Matrix E1:

Ghibli

Typhoon

Phoenix

Tornado

Direct motors on linear axes

For the movement of the axes, we use direct motors that eliminate the play and vibrations sometimes caused by timing belts, thus achieving a significantly higher dynamic response.

The removal of the belts also eliminates "noise," resulting in superior surface finish quality, even on the most complex surfaces.

Chip removal integrated into the structure.

The efficient chip removal system, active on the sides of the table with worm screws and a conveyor belt, keeps the machining area free from chip accumulations and ensures the safety of operators, allowing them to focus on more productive activities.

Stainless steel work area

The machining area, coated with modular stainless steel panels, ensures greater cleanliness and prevents damage caused by continuous exposure to dust and chips generated during machining.

Coin maintenance optimisé

The hydraulic and pneumatic oil units of the Matrix E1 are compactly and neatly grouped in a dedicated area to facilitate diagnostics and maintenance. The upper part, modular and scalable, is prepared for potential future expansion of the machine with new accessories and/or automation.

For cleaning and safety, the lower part of the panel includes a dedicated fluid collection tray to prevent any polluting liquids from being dispersed into the environment.

Disponible avec une table de positionnement

Matrix E1, like other Breton products, is optionally available with a wide range of rotary tables that can be integrated into the base. This allows for combined milling operations on cylindrical components or complex geometries.

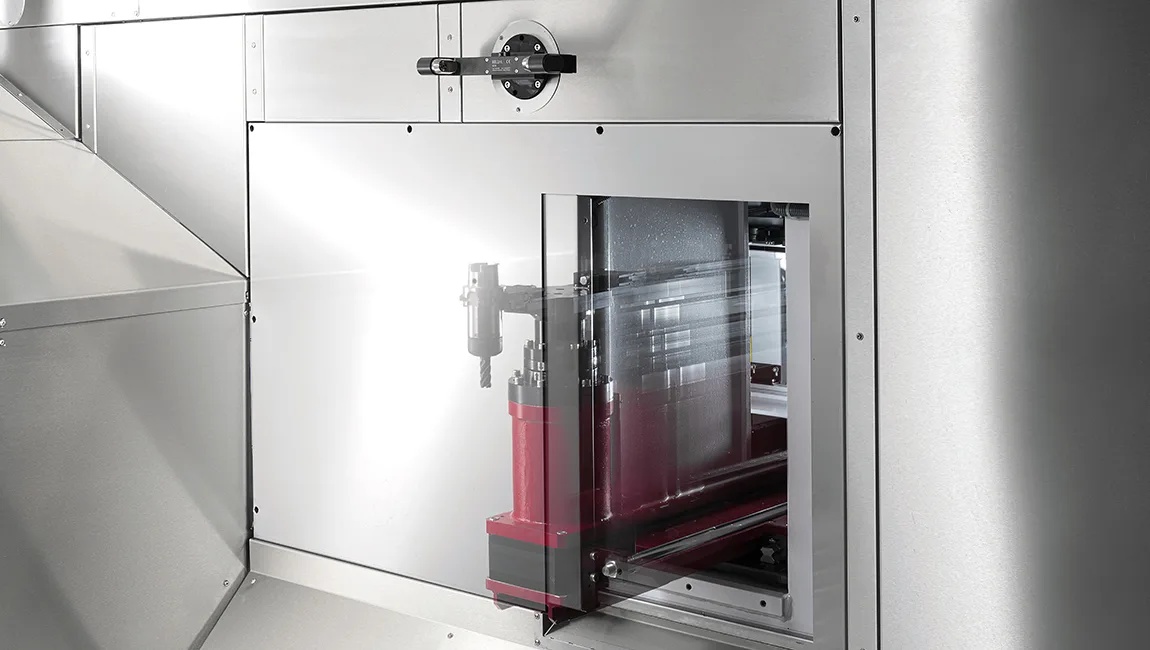

Changeur d'outils intégré dans la colonne

Matrix E1 can integrate different types of tool magazines, all of which can be perfectly interfaced with the new, even more compact and faster tool changer. This choice allowed us to design the column to be as rigid as possible while also leaving the possibility to expand or modify the magazine in the future if requirements evolve.

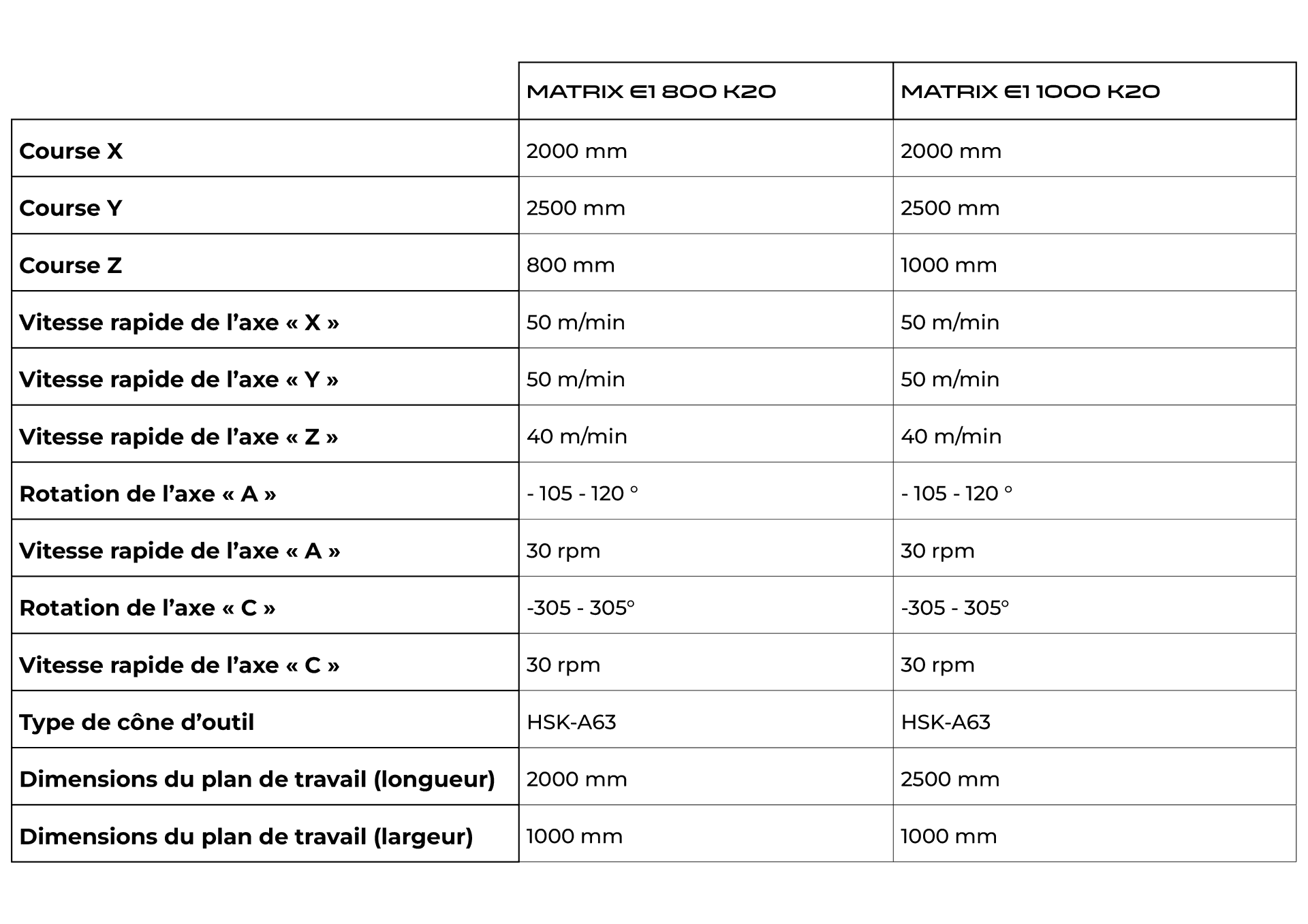

Versions de Matrix E1

Comparison table of versions

need more informations ?

Contact us !