Matrix E2

Brand: BRETON

Caractéristiques :

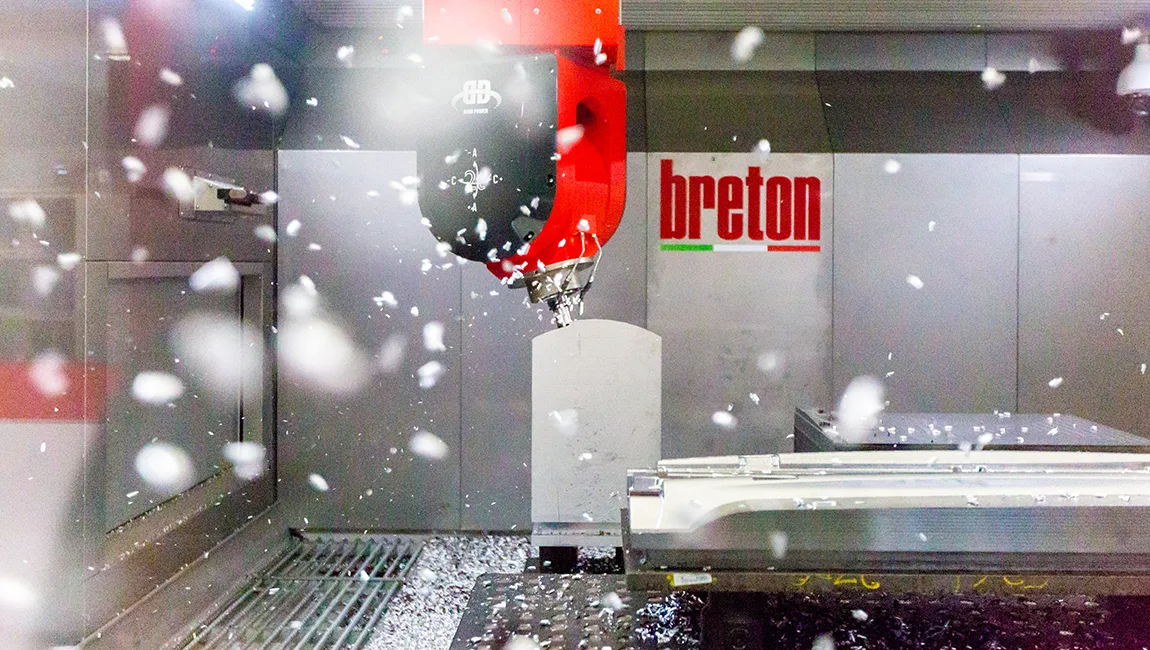

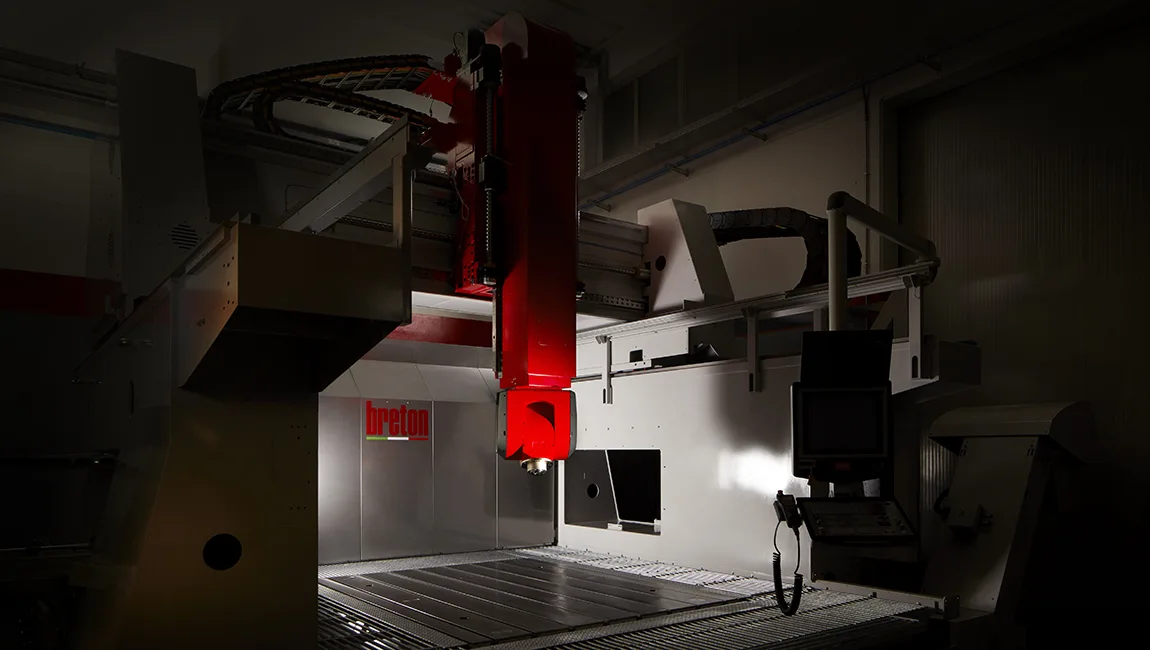

The Matrix E2 combines strength, speed, and precision with Dual Drive motors and advanced measurement systems. Its thermosymmetric structure with Thermal Shield minimizes deformations and operational costs. Designed for optimal ergonomics, it features an accessible table, enclosed machining area, and excellent visibility. Connected to Industry 4.0, it supports predictive maintenance and performance analysis. Available in two sizes with customizable options, it meets the needs of industries like aerospace and mold-making, offering advanced technologies such as ultrasonic cutting and automated taper machining.

The Matrix E2 combines strength, speed, and precision with Dual Drive motors and advanced measurement systems. Its thermosymmetric structure with Thermal Shield minimizes deformations and operational costs. Designed for optimal ergonomics, it features an accessible table, enclosed machining area, and excellent visibility. Connected to Industry 4.0, it supports predictive maintenance and performance analysis. Available in two sizes with customizable options, it meets the needs of industries like aerospace and mold-making, offering advanced technologies such as ultrasonic cutting and automated taper machining.

Vertical 5-axis gantry machining center, dynamic and high precision.

Its design is based on careful technical choices, balancing power and robustness with dynamic capabilities and high-level precision. This allows for optimal performance in roughing at high speed, semi-finishing, and finishing of medium to large-sized parts, in steel, lightweight alloys, or special composite materials.

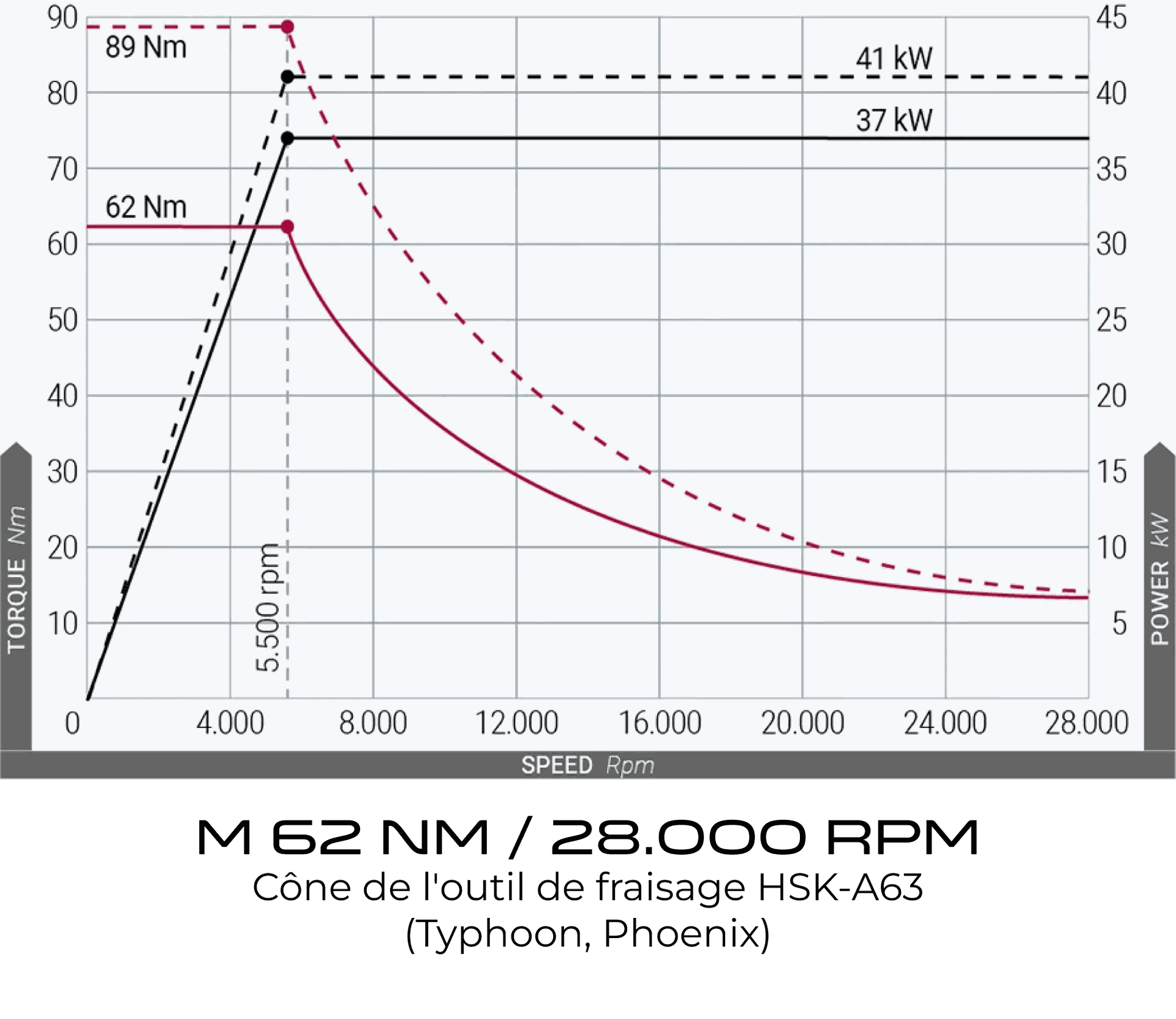

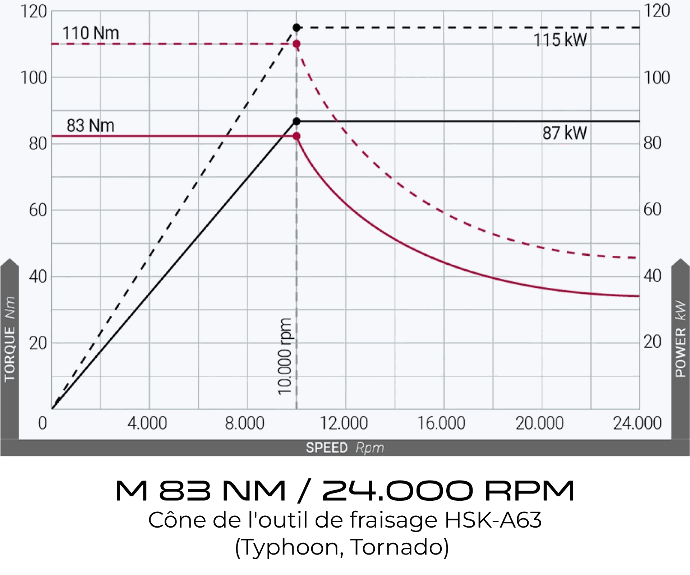

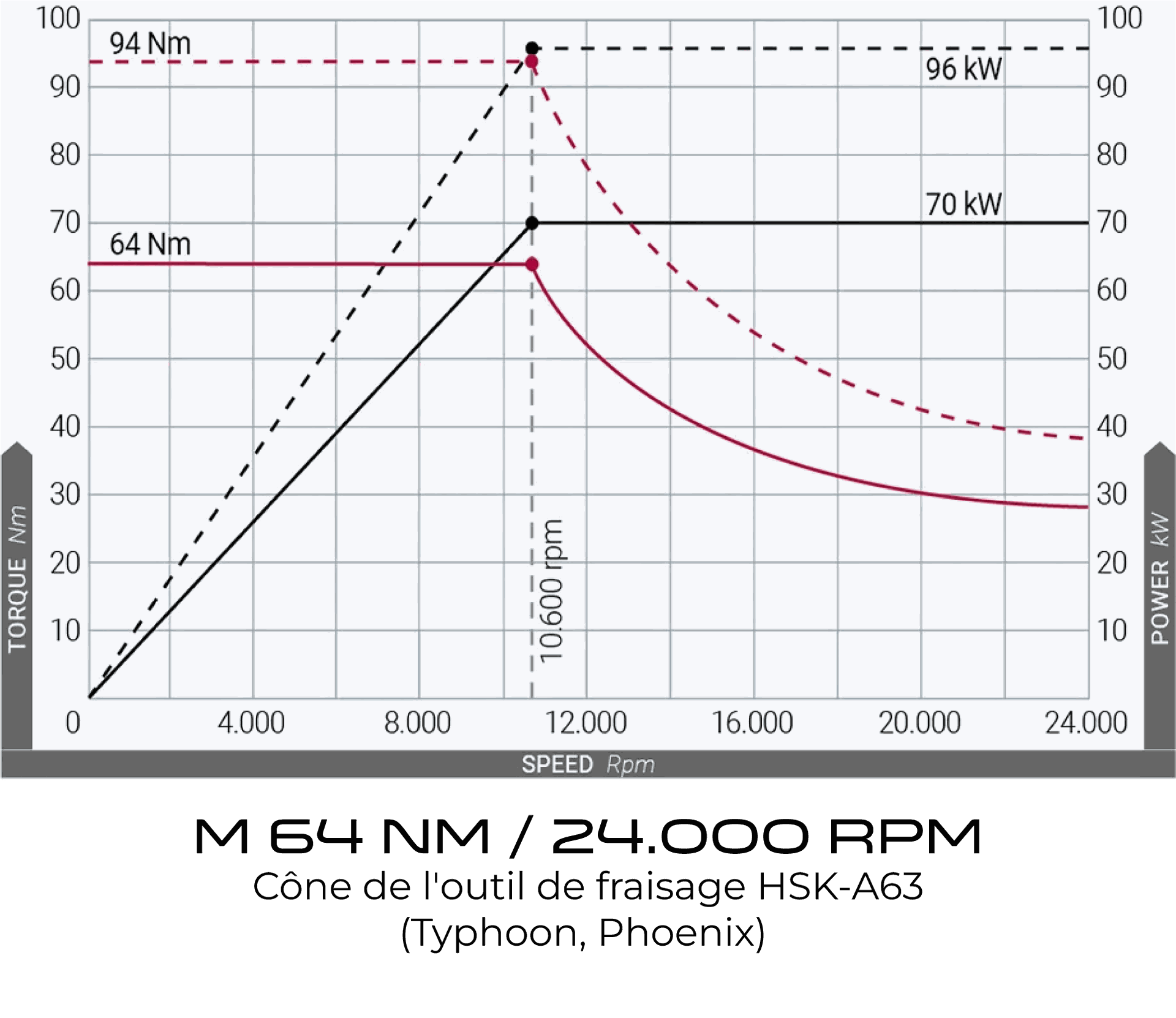

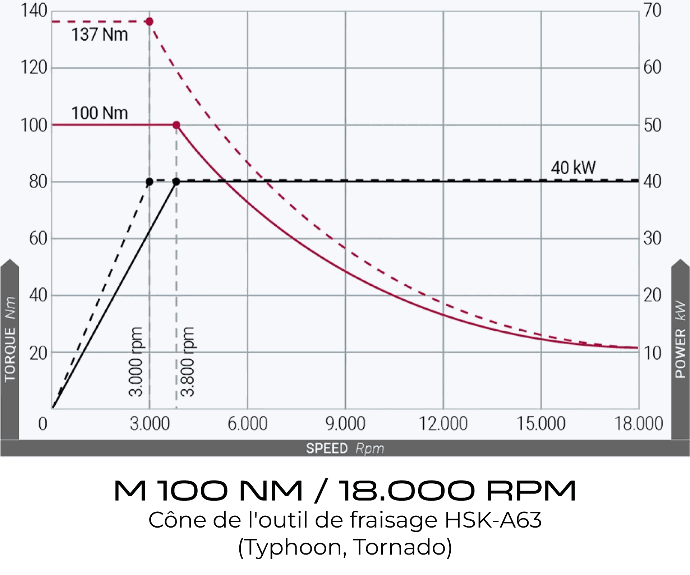

Heads compatible with Matrix E2:

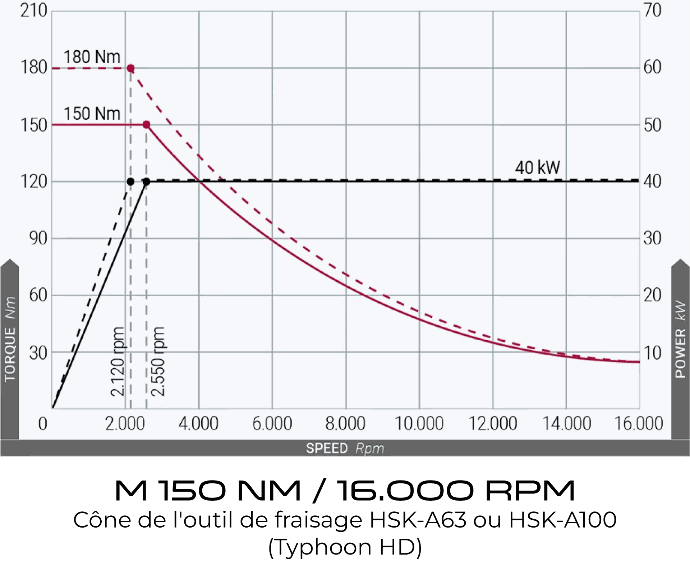

Typhoon

Typhoon HD

Phoenix

Tornado

Dual Drive Motors

The use of Dual Drive motorization ensures high force for the heaviest operations by harnessing the power of both motors pushing in the same direction to the maximum. For high-precision operations, the preload is automatically increased to achieve the highest level of accuracy.

The Dual Drive system reduces energy consumption compared to linear motors and does not require any cooling system.

Extremely robust slide

The entire Z-axis assembly is free of components that could interfere with the machining area, as the overall volume of the slide is equal to or smaller than that of the head. This is an advantage when machining deep parts or when movements in tight spaces are required. The movement is provided by two preloaded double-helix ball screws, while the sliding occurs on two robust rails at the rear, connected to the carriage by five slide blocks, all ensuring maximum stability.

Stainless steel work area

The machining area is covered with modular stainless steel panels that not only stay cleaner but also remain virtually unchanged over time, even when continuously exposed to dust and chips.

Tool changer integrated into the column or rotary tool magazine.

Matrix E2 can integrate different types of tool magazines, all of which can be perfectly interfaced with the new, more compact and faster tool changer. This choice allowed us to design the column as rigid as possible, while also leaving the option to expand or modify the magazine in the future as requirements evolve.

Optimized maintenance

The hydraulic and pneumatic oil units of the Matrix E2 are compactly and neatly grouped in a dedicated area to facilitate diagnostics and maintenance. The upper part, modular and scalable, is prepared for potential future expansion of the machine with new accessories and/or automation systems.

For cleaning and safety, the lower section of the panel includes a dedicated tray for fluid collection, ensuring that no polluting liquids are released into the environment.

Available with a positioning table

Matrix E2, like other Breton products, is optionally available with a wide range of rotary tables that can be integrated into the base. This enables combined milling operations on cylindrical elements or complex geometries.

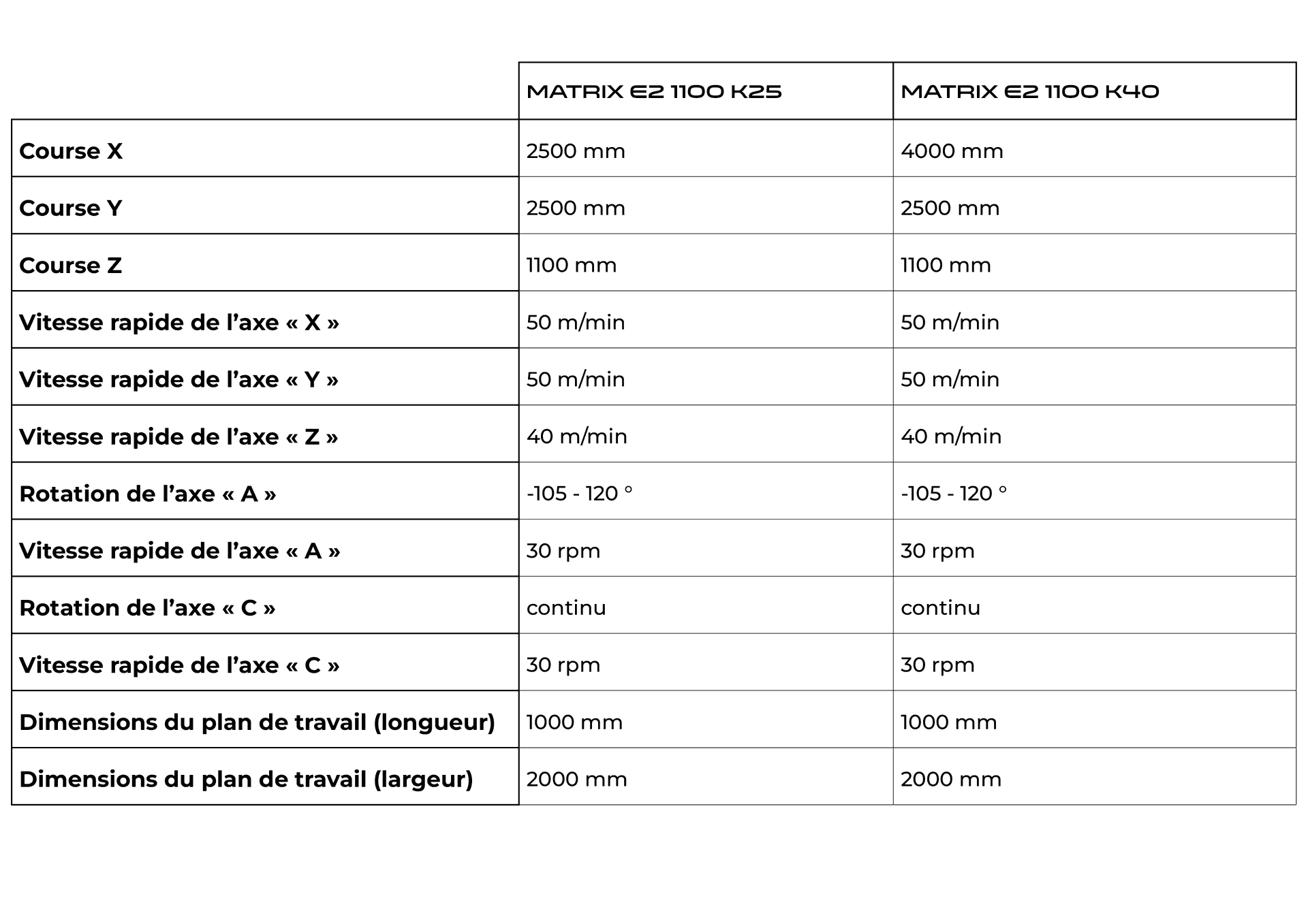

Matrix E2 versions

Comparison table of versions

need more informations ?

Contact us !