DDM type servobrake electric press brake

Brand: DENER

Caractéristiques :

- Energy consumption reduced by 50% compared to hydraulic models.

- High efficiency and precision.

- Quiet and fast operation.

- Throat width equal to bending length.

- Standard PROMECAM/AMADA tool clamping system.

- Low maintenance requirements.

- Intuitive and user-friendly ESA CNC control.

- Force distribution ensured by a belt system (block and tackle type).

- Automatic calculation of bending steps for STEP and DXF files.

- Up to 35% faster than a hydraulic press brake.

servobrake electric pressbrake

The Dener DDM CNC servobrake press brakes are reliable and eco-friendly machines. The DDM servobrake series is known for its high execution speed, exceptional precision, and wide dimensional range, allowing you to process sheets up to 4 meters long, fully electric, with low energy consumption and minimal maintenance.

They come equipped with a standard ESA CNC controller, a precise clamping system for punches and dies of the PROMECAM/AMADA type (standard), and a multi-axis backgauge system, enabling cost-effective sheet metal bending.

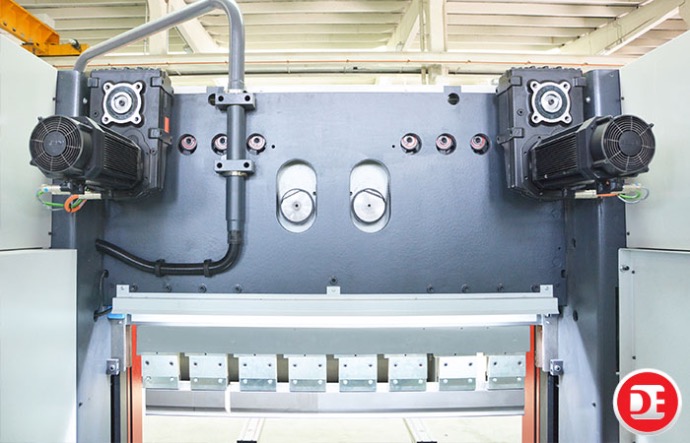

Slider movement

Pressure distribution along the bending length is ensured by a high-resistance belt system, "muffling" type.

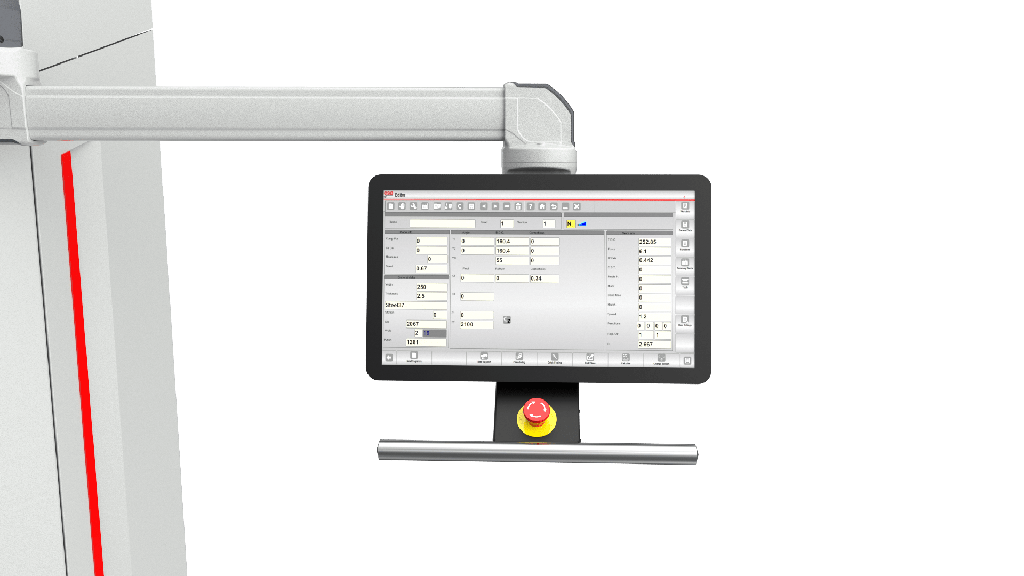

ESA 675W CNC controller 3D touch screen 21".

Backgauge fingers

Two backgauge fingers as standard, up to six available as an option (depending on the choice of multi-axis backgauge).

WILA-type clamping system (optional)

Optional WILA clamping system with hydraulic upper and lower clamping available.

Ram return system

The return of the ram is ensured by high-resistance springs, reducing both machine footprint and cost.

Bending force

The bending force is provided by two gear motors, Y1 and Y2.

standard equipment

Punch and die holder of PROMECAM/AMADA type.

ESA 875 W control unit, 21″ 3D touchscreen

4 axes – Y1, Y2, X, R.

- Automatic crowning table.

- Front protection with DSP laser.

Side and rear safety doors..

Remote foot pedal with emergency stop button.

- 2 front sheet supports.

Power supply: 380 V, 50-60 Hz, 3Ph.

Electrical cabinet air conditioning system.

Options

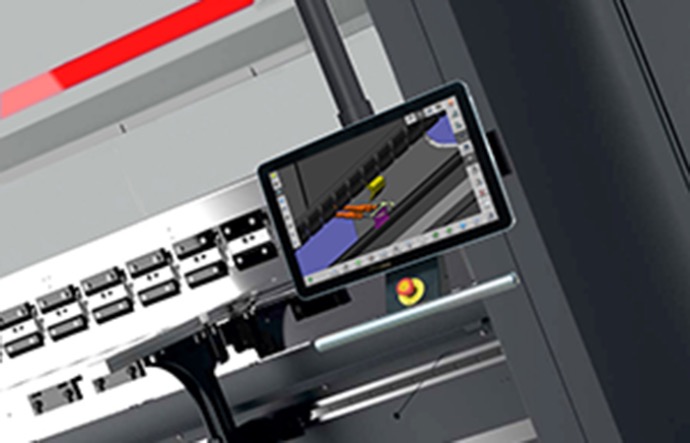

Delem DA 66T control unit..

Delem DA 69T 3D control unit.

ATF Tipi backgauge X1 X2 R1 R2 Z1 Z2

butée arrière X1 X2 R Z1 Z2.

Backgauge X Prime.

- Fiessler Akas 2 M(P) laser safety system.

- Manual or CNC-controlled crowning.

- CE-compliant bending laser.

- Motorized front sheet follower.

- WILA mechanical tool clamping system.

- WILA hydraulic tool clamping system.

need more informations ?

Contact us !