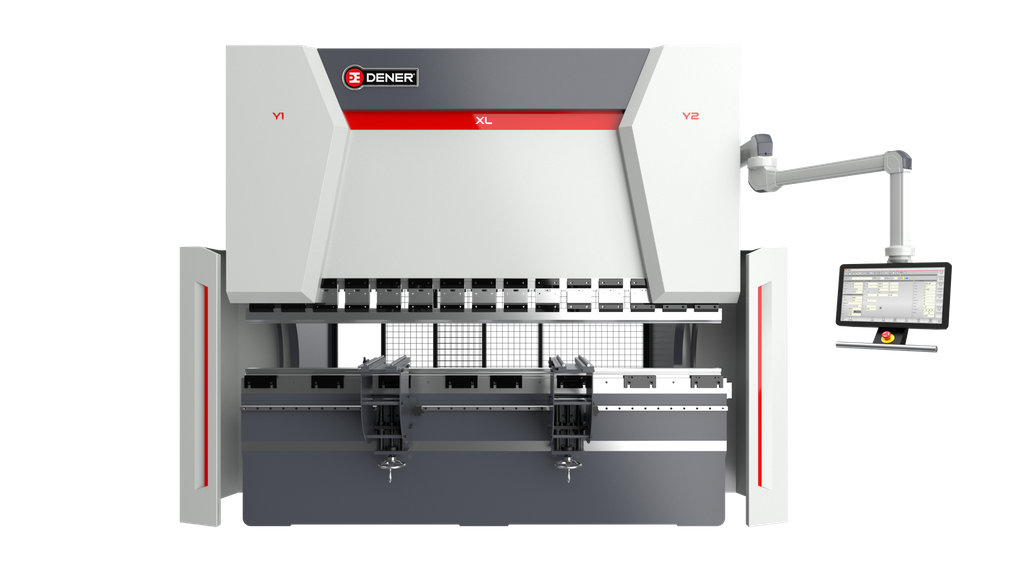

Smart XL hydraulic press brake

Brand: DENER

Caractéristiques :

- Precise and high-quality bending.

- Reinforced structure with stress reduction.

- Increased throat depth (400 mm to 600 mm depending on tonnage).

- Extended stroke range (300 mm to 455 mm) based on tonnage and bending length.

- Wider opening (530 mm to 680 mm) depending on tonnage and bending length.

- Reinforced hydraulic system with internal gear pump for faster and quieter operation.

- Permanent ram guidance via 4 contact points.

- Standard PROMECAM/AMADA tool holder.

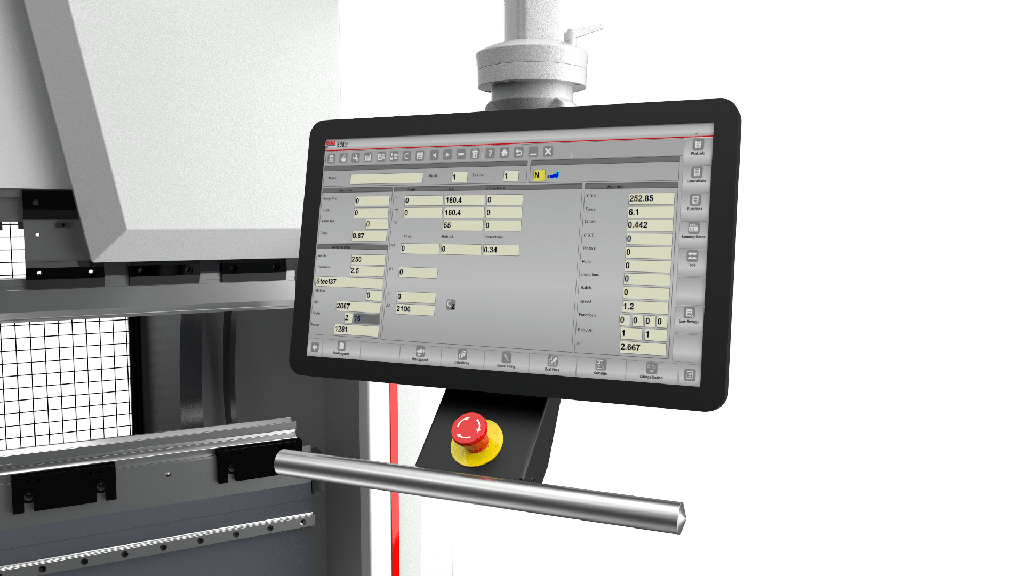

- ESA S 640 CNC controller with a 15" 2D touchscreen and 3D visualization.

- High-quality hydraulic components.

- Easy maintenance and servicing.

smart XL hydraulic press brake

The Dener SMART XL CNC press brakes are designed to be user-friendly, reliable, and high-performing. They incorporate manufacturing technologies that ensure a high level of quality. This model comes standard with a 15" 2D graphical CNC controller, touchscreen type ESA 640, offering quick machine handling and simple part programming via the touchscreen interface.

With standard 2D programming functions and optional 3D capabilities, the Metalix software allows for automatic generation of bending sequences, bend loss calculations, and the creation of a library containing the history of your productions.

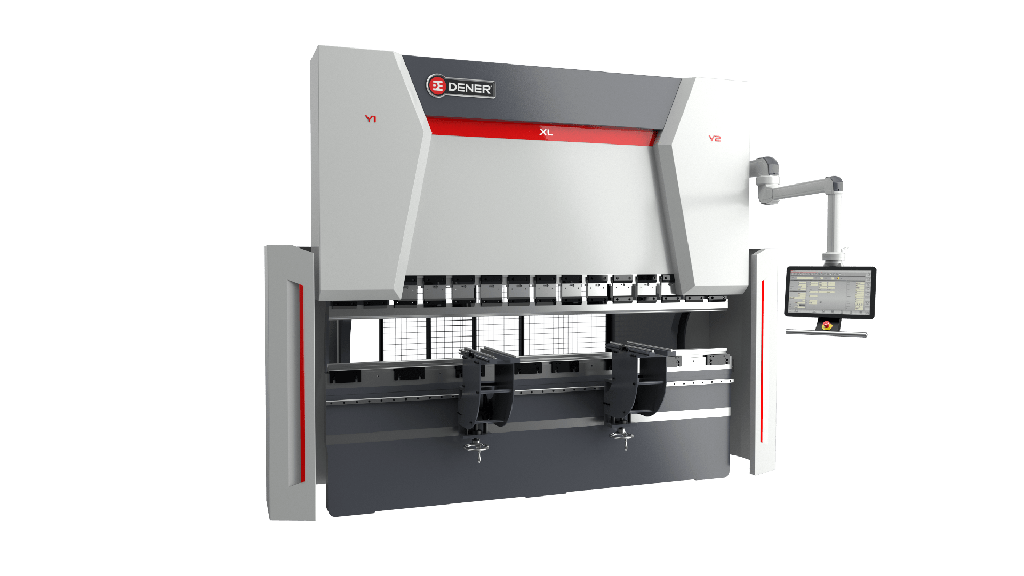

Gooseneck depth, stroke and opening with high capacity

Thanks to its larger opening, stroke, and gooseneck depth compared to competitors, this machine allows for easy bending of a wide variety of part sizes.

Standard 3-axis machine

(Y1-Y2-X)

The back gauge of the Smart XL range is made from a one-piece cast aluminum body. It plays a crucial role in ensuring bend quality and achieving precise parts. Whether working on simple components or complex multi-step pieces, this back gauge can be extended to 6 axes depending on your requirements.

Standard ESA S 640 15" 2D controller

Parts to be bent can be drawn directly on the touchscreen or input by the operator via the step-by-step automatic bending system. The CNC controller optimizes bending plans to improve efficiency.

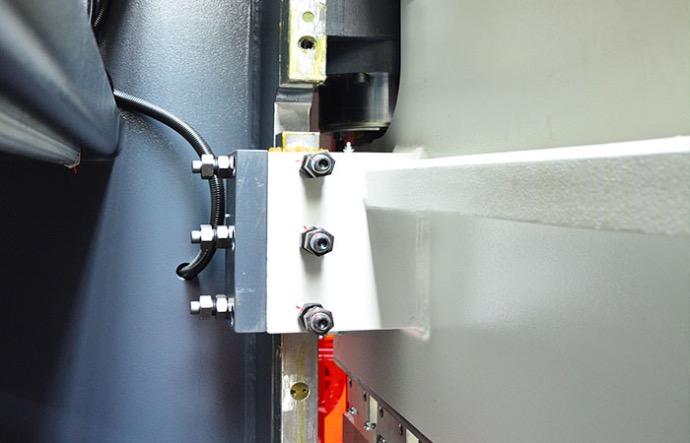

High-rigidity ram guiding system

This permanent 4-point contact guiding system provides greater movement stability and precision.

Manual crowning table adjustment as standard

Automatic crowning table adjustment available as an option.

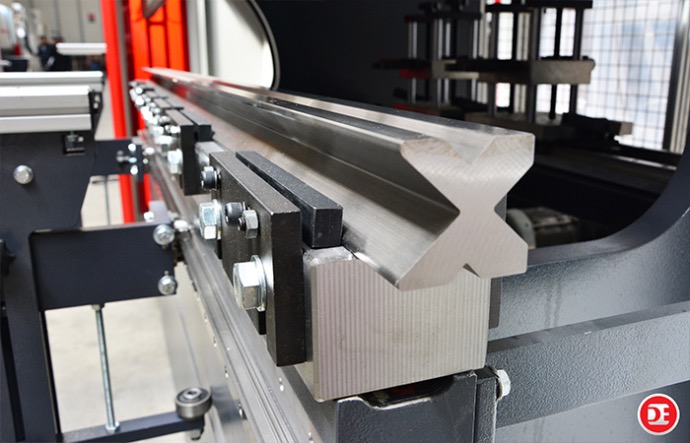

Standard PROMECAM/AMADA punch/die tool holder system

We provide standard PROMECAM/AMADA-type punch and die clamping systems, which can be adapted to meet specific customer needs.

standard

Equipements

Axes Y1, Y2, X.

- Punch/matrix holder type PROMECAM/AMADA.

- CNC control with 15" 2D touchscreen display, Esa S 640 type.

- Manual crowning.

- Crowning depth from 450 to 600 mm depending on tonnage.

- Ram stroke from 320 mm to 455 mm depending on tonnage

- Hydraulic components Hoerbiger or Rexroth.

- Remote pedal with emergency stop button.

Side and rear safety doors.

More details

Options

- ESA S 875 W 3D control unit with 21" touchscreen for managing 4 or more axes.

- Delem 66T CNC control unit.

- Delem 69T 3D CNC control unit.

- Cybelec ModEva 15T 3D CNC control unit.

- Backgauge type X R.

- Backgauge type X R Z1 Z2.

- Adjustable front sheet supports guided by linear rails.

- Bending laser.

- Electrical cabinet air conditioning system.

- CNC automatic crowning.

- Quick clamping system for punches.

- Pneumatic tool clamping system.

- Mechanical or hydraulic tool clamping system, Wila type.

need more informations ?

Contact us !