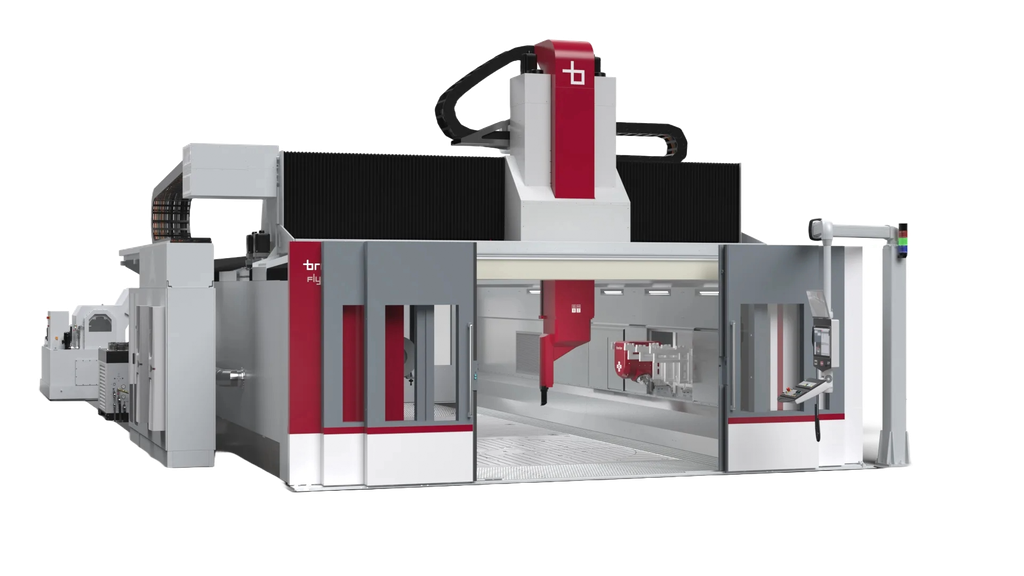

Flymill

Brand: BRETON

Caractéristiques :

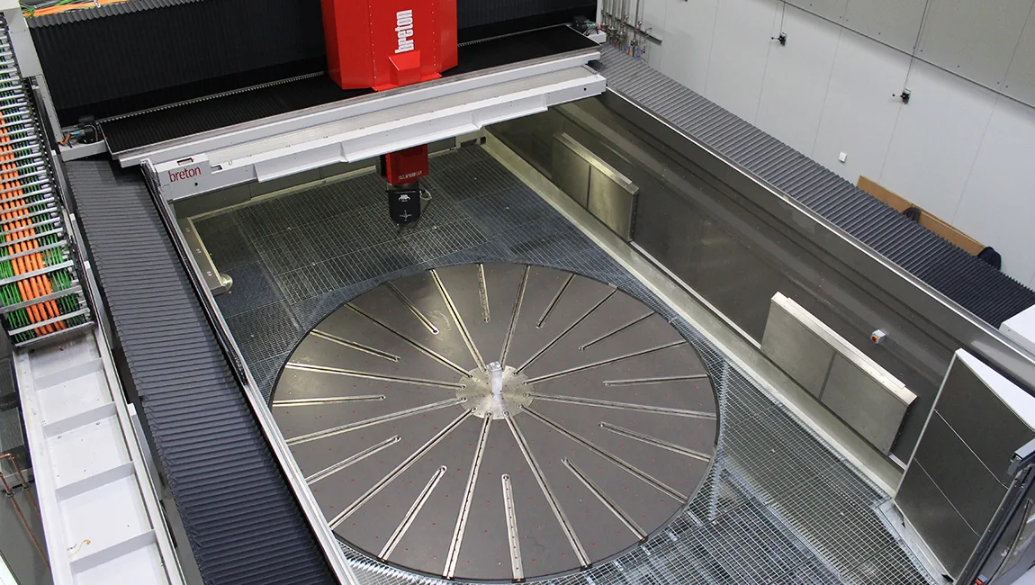

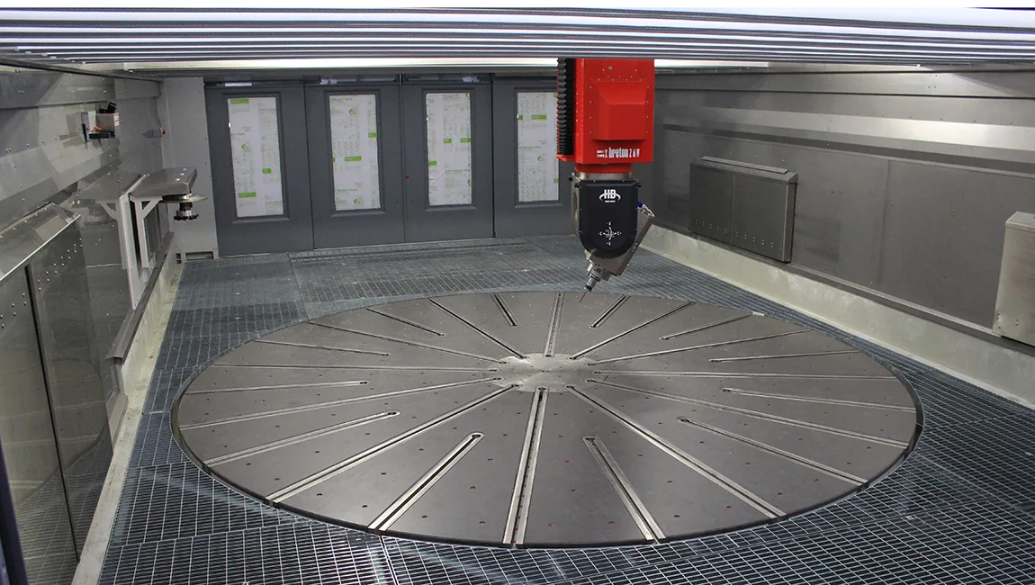

Breton Flymill is the machining centre designed for companies operating with very large workpieces and, especially, for machining of tough materials that require high power and torque.

With Z axis strokes up to 1,500 mm, cross strokes up to 4,000 mm and longitudinal strokes up to 30,000 mm, Flymill is the machining centre for tough materials with the highest operating volume in the Breton range.

This machine is distinguished by its ability to combine milling and turning in a single set-up, exploiting the potential of the turning table and the automatic heads store to automatically switch from the powerful milling head to the boring bar head during the machining process.

5-axis modular gantry vertical machining center, high power and extremely high precision

A combination of strength and precision on large dimensions to achieve maximum performance in roughing, semi-finishing, and finishing operations on parts made of tough materials, steel, or light alloys.

Also available in a milling and turning version (Flymill MT), which combines the functions of a vertical lathe with those of a continuous 5-axis milling machine, thus expanding the range of applications that can be carried out in a single setup.

Flymill compatible heads:

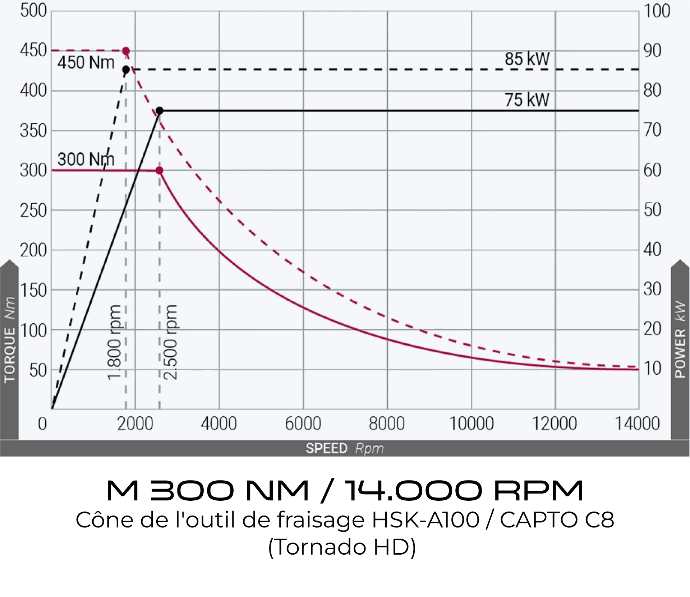

Tornado HD

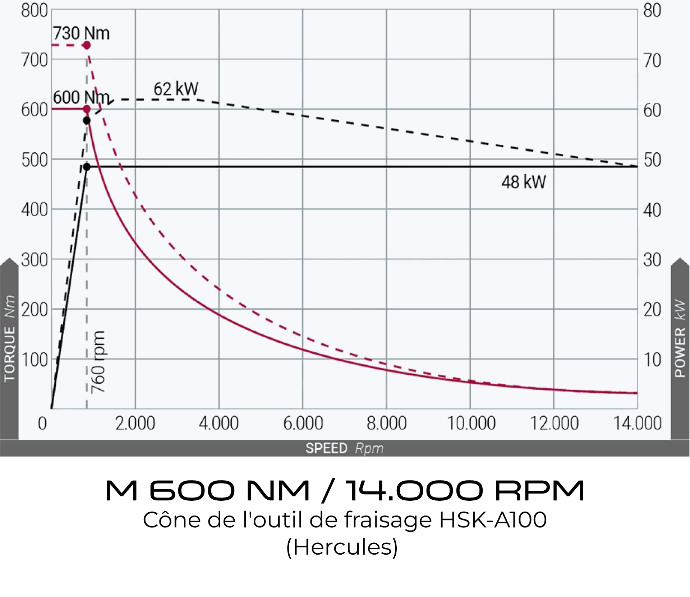

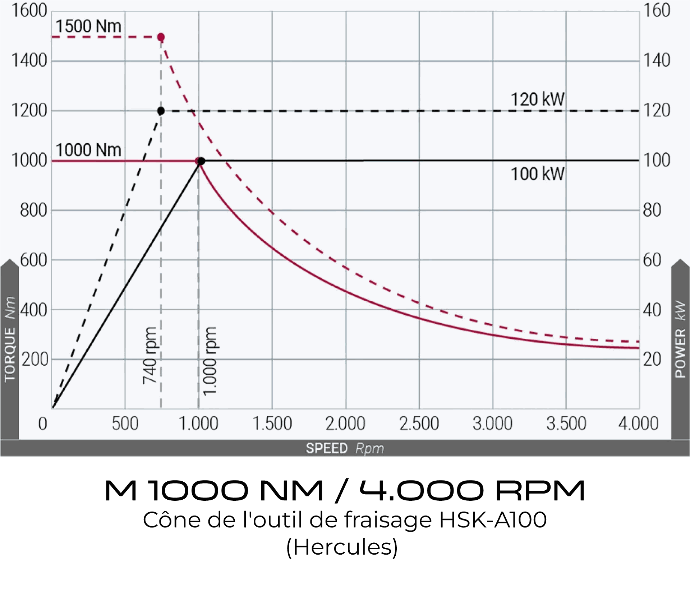

Hercules

TTVO

DUAL DRIVE MOTORS

The use of Dual Drive motorization ensures high force for the heaviest operations by harnessing the full power of two motors pushing in the same direction. For high-precision operations, the preload is automatically increased to achieve maximum accuracy.

The Dual Drive system consumes less energy compared to linear motors and requires no cooling system.

EXTREMELY ROBUST RAM

The entire Z-axis assembly is free of components that could interfere with the machining area, as the overall volume of the carriage is equal to or smaller than that of the head. This is advantageous when machining deep parts or when movement in confined spaces is required. The movement is driven by two preloaded double-helix ball screws, while the sliding is supported by two robust rails at the back, connected to the carriage by five sliding blocks, all ensuring maximum stability.

TOOL CHANGER INTEGRATED IN THE COLUMN OR ROTARY TOOL MAGAZINE

Flymill can integrate various types of tool changers, all of which can be perfectly interfaced with the new tool changer, even more compact and faster. This choice has allowed us to design the column to be as rigid as possible while also leaving the possibility of expanding or modifying the tool changer in the future if requirements evolve.

OPTIMIZED MAINTENANCE

Optimization of the entire electrical cabinet and maintenance area. The hydraulic and pneumatic power units have been grouped in an orderly and compact manner, keeping all necessary diagnostic and maintenance modules within view. Designed to be modular and scalable, it allows for potential future expansion of the machine with new accessories and/or automation systems.

Wide range of rotary tables

Whether milling or turning, Breton manufactures its machining tables in-house, using both consolidated solutions, such as hydrostatic technology, and innovating with the use of direct-drive motors, even on large-sized tables.

Turning and milling in a single machining center

The head change system, combined with the ability to mount turning heads and high-performance rotary tables, makes Flymill – in its MT (Mill Turn) version – the ideal solution for the general mechanics sector and for machining circular parts in the aerospace industry.

One machining center combines the optimal milling capabilities of 5-axis machining centers with the turning performance typical of vertical turning centers.

Implementations:

need more informations ?

Contact us !