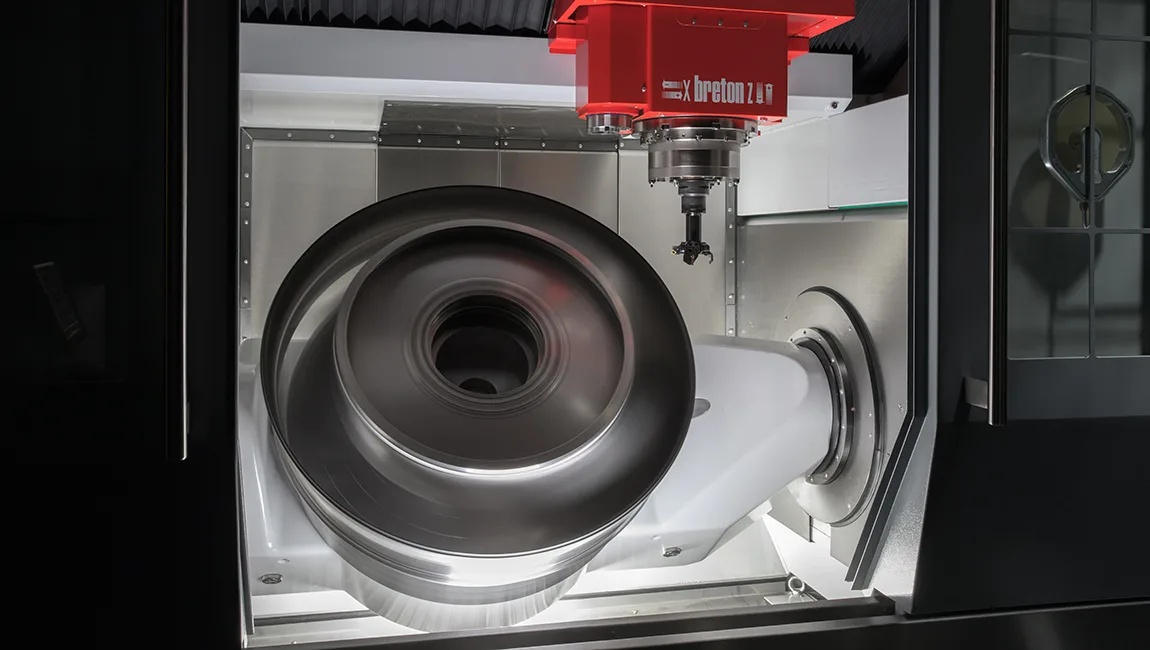

Ultrix

Brand: BRETON

Caractéristiques :

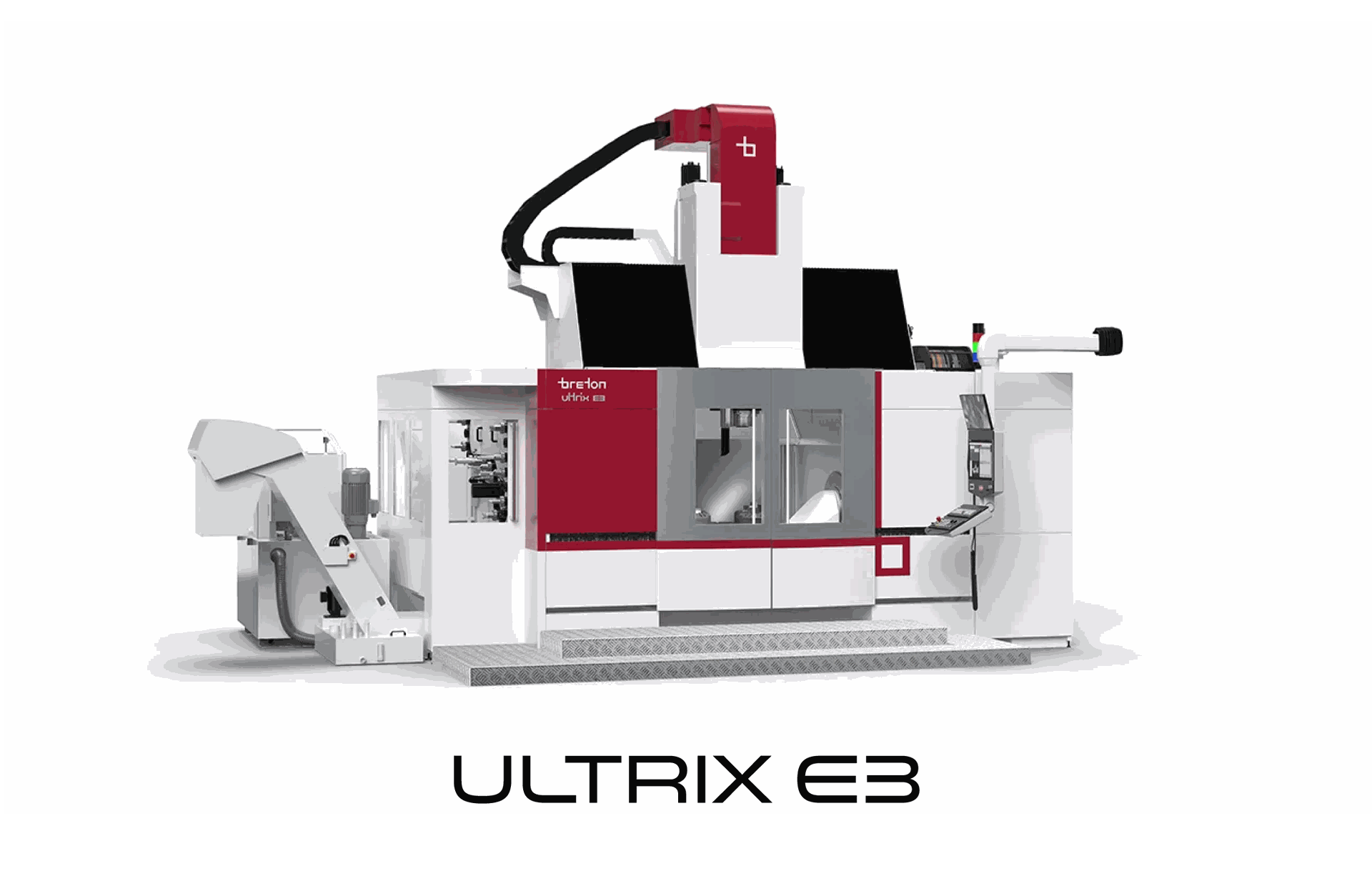

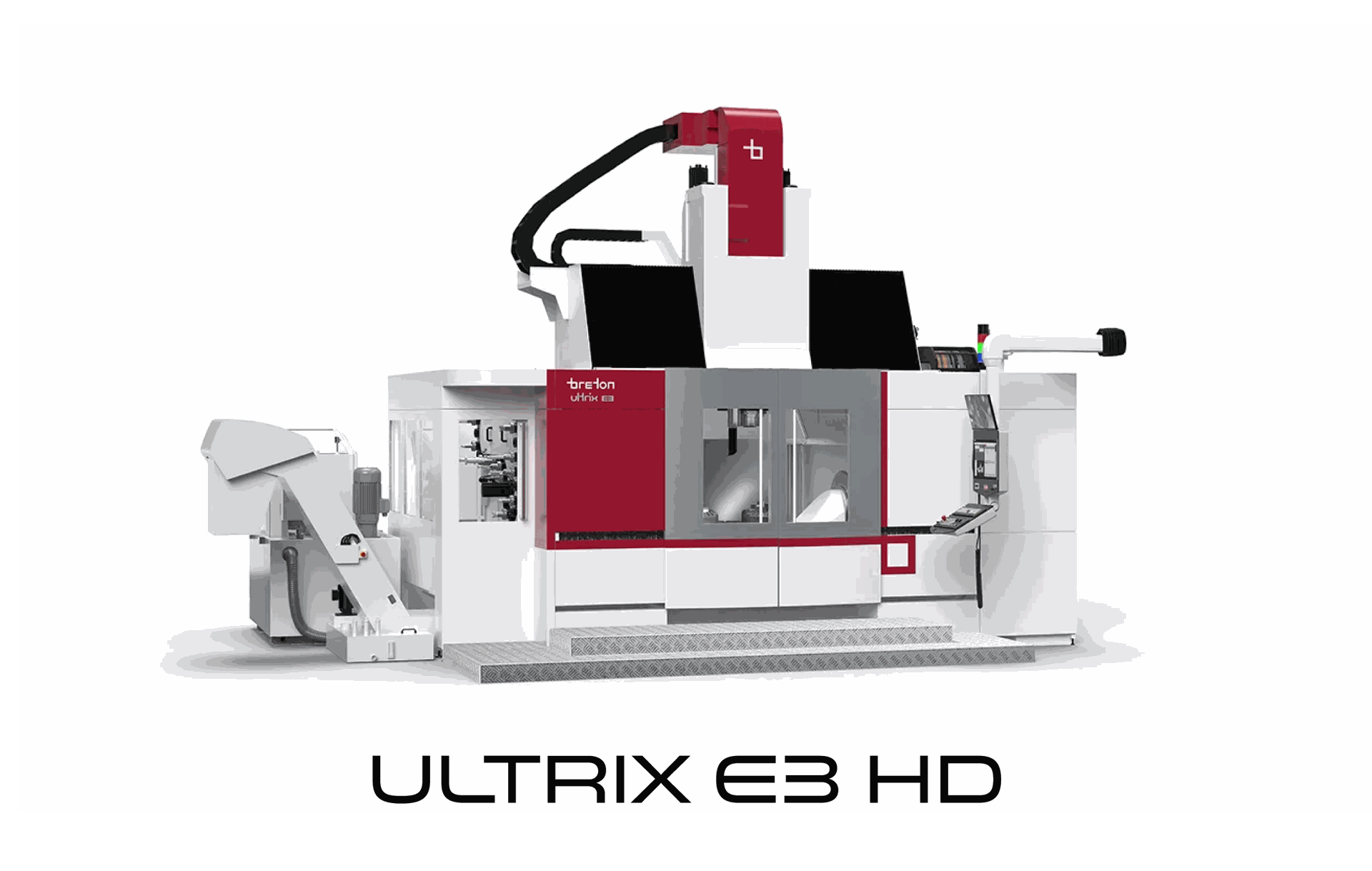

The Breton Ultrix series combines milling and turning for medium to large parts made from titanium, steel, or composites with precision and efficiency. Featuring a tilting rotary table and vertical spindle, it is ideal for aerospace engine components. The flagship Ultrix E3 offers travels up to 1700x1700x1000 mm. With easy loading, a durable stainless steel work area, pressurized axes, and optimized accessibility, it ensures smooth and efficient operations. Automatic angular head changes enhance flexibility for diverse machining needs.

5-axis vertical machining center with a swiveling rotary table, monoblock design, for milling and turning.

A robust and stable Metalquartz base and a dedicated turning bar allow for a full range of operations in a single machining center. Ideal for roughing, semi-finishing, and finishing operations on superalloy, steel, lightweight alloys, or composite materials.

Pins compatible with Ultrix:

SWIVEL-ROTARY TABLES WITH TORQUE MOTORS

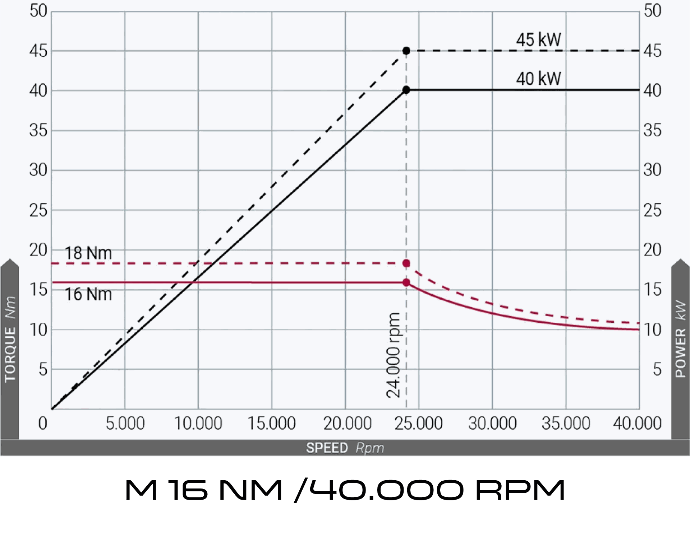

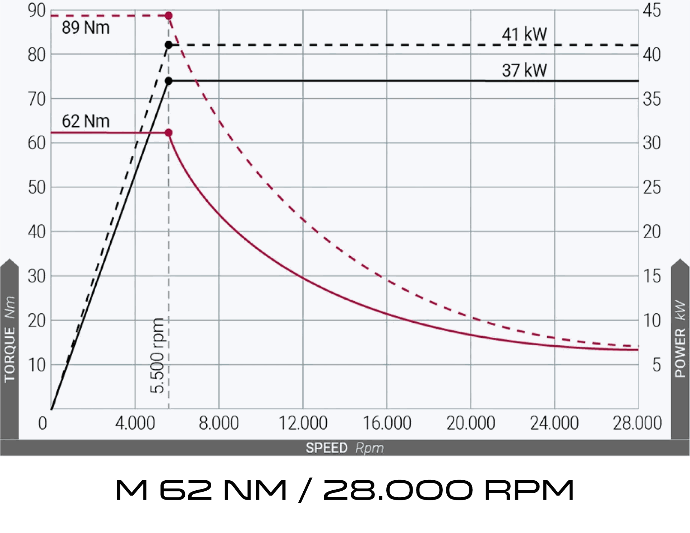

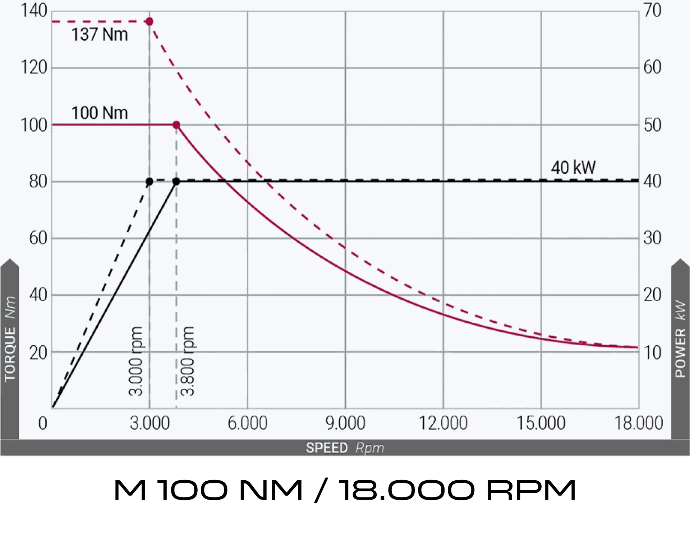

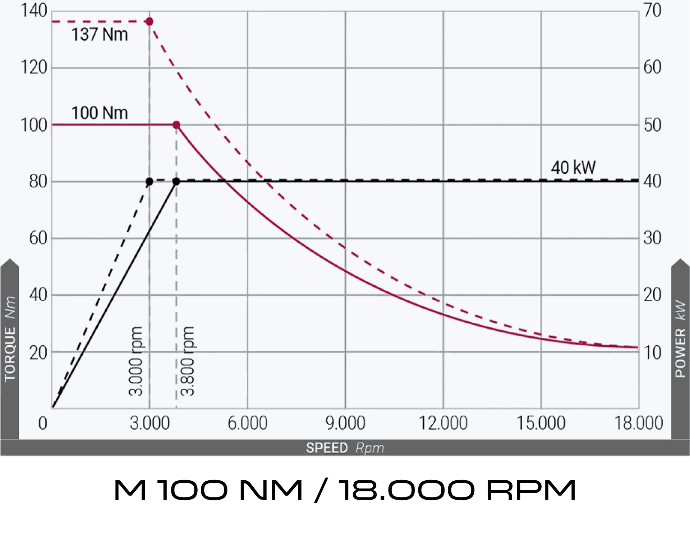

The machine features a series of high-performance swivel-rotary tables equipped with direct drive technology.

DEDICATED TURNING BAR

Ultrix has a vertically mounted turning bar rigidly fixed to the vertical structure of the vertical slide, whose position is controlled and, thanks to powerful hydraulic brakes, can be locked at any point of its vertical travel.

METALQUARTZ BASE

The base is made of Metalquartz to ensure maximum rigidity and stability, providing the operator with the best ergonomics and comfort of use for easy and secure access to the machine.

OPTIMIZED MAINTENANCE

Optimization of the entire electrical cabinet and maintenance area. The hydraulic and pneumatic oil units have been grouped in an orderly and compact manner, keeping all the necessary modules for diagnostics and maintenance easily accessible. Designed to be modular and scalable, it allows for future expansion of the machine with new accessories and/or automation.

TOOL CHANGER INTEGRATED INTO THE COLUMN OR ROTARY TOOL MAGAZINE

Ultras can integrate different types of tool magazines, all perfectly compatible with the new fast and compact tool changer. This solution, which uses a small opening in the machine's column, allows for maintaining maximum structural rigidity while offering a wide range of options for positioning the tool magazine.

DIGITAL TWIN

Breton Ultrix was designed by harnessing the potential of the Digital Twin. In a virtual environment, all the machine's features were included to create a realistic simulation and verify its behavior in different usage scenarios. The result is a structure built based on these simulations, which allowed for targeted optimization and an increase in performance.

FULLY ENCLOSED WORKING AREA COATED WITH STAINLESS STEEL

A clean machine lasts much longer. This is why the machining area is covered with modular stainless steel panels that are not only easy to clean but also remain virtually unchanged over time, even when constantly exposed to dust and chips.

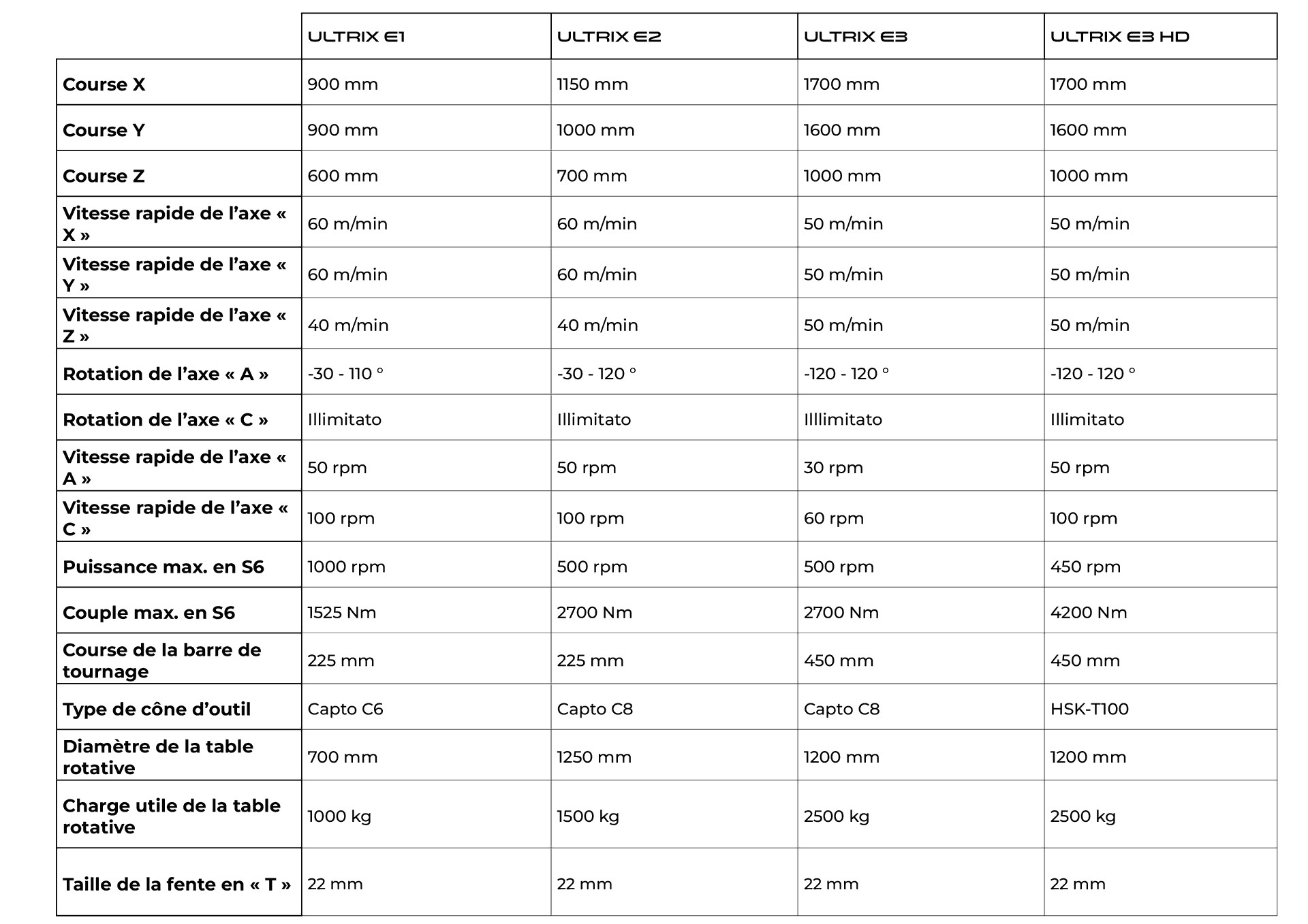

Ultrix versions

Comparison table of versions

need more informations?

Contact us !